- Mission

-

- As there are less mass-produced products which means most of products are unique and each one is measured manually, it takes enormous time. In addition to it, the measurement result depends on the operator and measurement omissions may occur.

- Because the size exceeds several meters to several tens of meters, two-person work is essential.

- Since using paper drawings for dimension management is main, it takes time for OK/NG judgement and there can be misjudgement.

- In some cases, the number of measurement samples cannot be earned due to man-hours and product trend management cannot be completed.

- There is a lot of work to be done, from filling out paper drawings to entering information in Excel, and each time there is a loss of several hours and input errors.

- The measurement process requires techniques and a lot of man-hours for training.

Solution

We can quickly and easily measure large parts that are difficult to measure on site, and use the latest technology, such as virtual assembly, to shorten or eliminate the temporary assembly process and significantly reduce rework on site.

And the measurement result is accurately quantified, which leads to visualization of problems in each process.

It greatly contributes to the promotion of *i-Construction.

*”i-Construction” is an initiative promoted by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) of Japan that aims to improve the productivity of the entire construction production system by introducing measures such as the “Comprehensive use of ICT (ICT earthwork)” to construction sites.

Proposal Contents

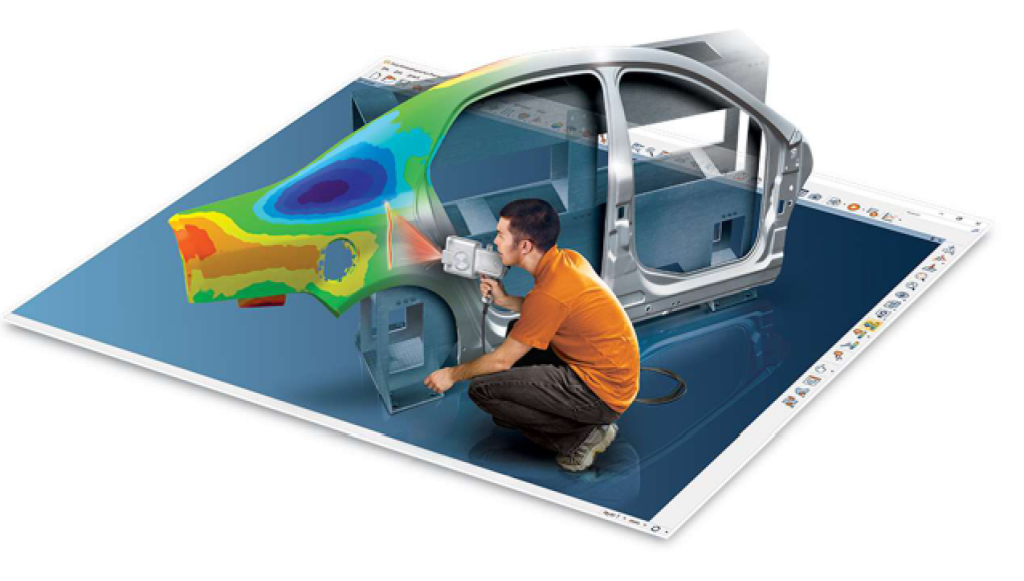

1. By utilizing the Leica laser tracker system, the manufacturing man-hours were significantly reduced.

The Leica Laser Tracker can accurately measure workpieces over several tens of meters. By using the T-Probe system, which is one of the attachments, there are many cases where the work time has been reduced by 50% or more compared to the conventional system.

Unlike conventional manual measurement, the variation in measurement can be minimized.

In addition, the T-Probe can be used for both measuring and marking tasks as it is capable of punching.

2. Measurement using CAD data (without paper drawings)

If you set the measurement points or set up a measurement macro in CAD in advance, the measurement points will be guided on the software, so anyone can easily and efficiently measure without paper drawings, and there will be no measurement omissions. In addition, the number of operators can be reduced from two to one, as there is no need for a measurement supervisor. No more difficult training is required, either.

3. Bridge segment measurement

Quick measurement of dimensions, hole positions, edges of interfering parts, and markings can be made with a minimum steps. It is also possible to confirm the shape of the workpiece, which can be used to check for torsion, strain and corrosion.

4. Optimization of welding conditions and inter-process analysis (using the world’s first ultra-large laser scanner.)

The LAS-XL scanner (non-contact scanner) can scan large structures. Strain and deformation analysis during welding can be easily performed, which leads to optimization of the welding process and inter-process management in trial production, and can prevent problems in advance.

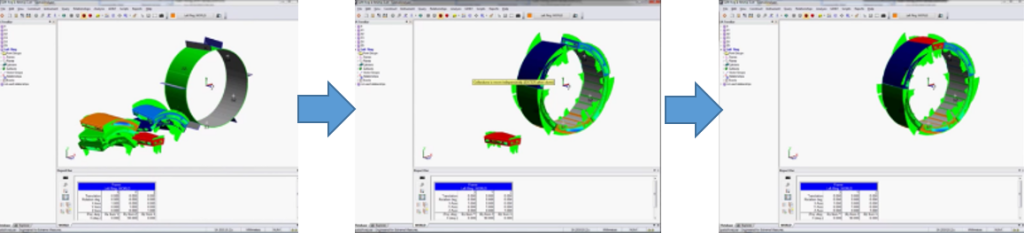

5. Digital Assembly

In the case of bridge segments, virtual assembly can be performed using measured data such as hole positions.

Therefore, it is possible to judge whether or not a product can be assembled without temporary assembly of the actual product, which leads to the reduction of temporary assembly work.

6. Creation of automatic report & statistics function

TTS can also customize and produce reports and statistics, which can be used to automatically output numerical and statistical data from the dedicated reports after measurement. The automation reduces the time spent on inputting and creating reports to zero, and the measurement data can be stored as digital data and archived for use whenever needed.

System Configuration

Reflector