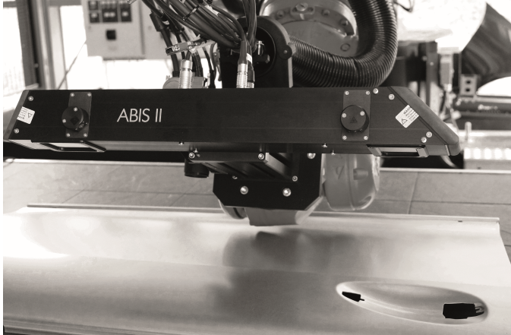

Non-contact surface inspection system

- Product Description

-

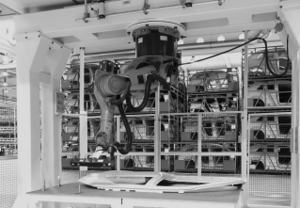

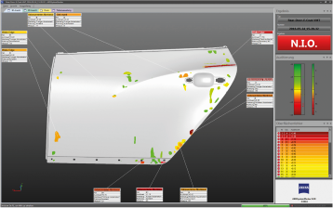

ABIS II is good at detecting surface distortions quickly and easily either off-line or in-line and requires no special skills. Furthermore, it can also automatically measure and determine various types of distortions on a white vehicle body, a surface on which it is normally very difficult to find distortions. It can achieve the same level of results as those obtained from inspections and classification evaluations performed by experts in the past. Defects that cause customer complaints can be removed at an early stage after paint coating due to this high accuracy automatic detection.

Product Features

- Reduces negative costs due to distortion detection before coating

- A stable distortion detection standard that does not rely on the skill of an inspector

- Outputs analysis results immediately

- Achieves total inspection in a line

- Detects various types of distortions that occur during the manufacturing process

Product Specifications

| Sensor size | 670×80×100 |

|---|---|

| Sensor weight | 4.7kg |

| Measuring time | 0.1ms |

| Measuring area per single shot | 200×300mm |

| CCD camera resolution | 1200×1600 pixels |

| Minimum depth of detectable distortion | 10μ(depends on surface condition) |

| Minimum width of detectable distortion | 1.5mm |

| Stand off | 432mm±20mm |

| Light source | Xenon flash |