Comet Yxlon’s CT scanning systems are globally recognized for delivering high-precision and high-resolution non-destructive testing (NDT). As a leader in industrial X-ray and computed tomography (CT) systems, Comet Yxlon provides state-of-the-art technologies that are widely used across various industries, including automotive, aerospace, electronics, medical devices, and research & development.

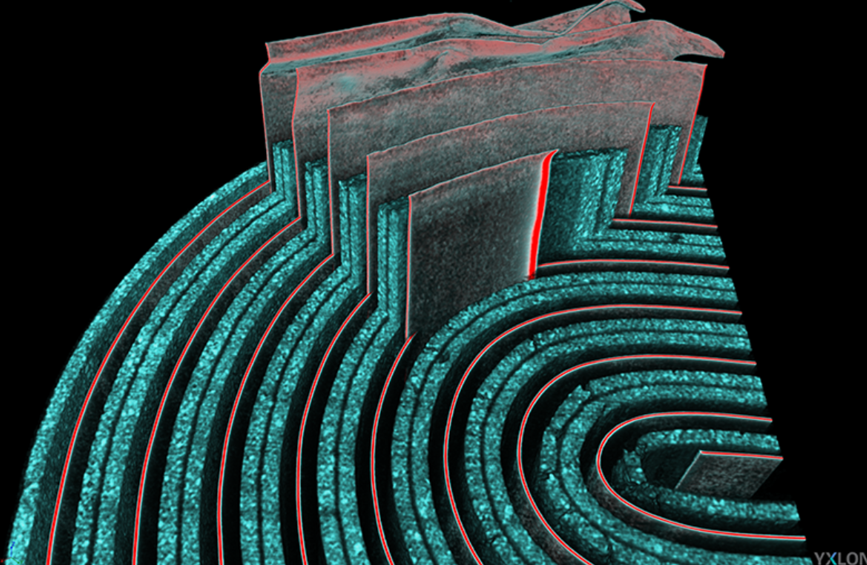

Computed Tomography (CT) is a technique that uses X-rays to non-destructively capture internal structures of an object and reconstruct them into detailed three-dimensional (3D) images. Industrial CT scanning plays a crucial role in quality assurance, non-destructive evaluation, material analysis, and reverse engineering across a broad range of applications.

Airbag

CT image of an airbag

High-Precision NDT for 3D Visualization of Defects

3D CT Image of a Lithium-Ion Battery

Comet Yxlon’s CT scanning systems utilize advanced microfocus X-ray technology to enable high-precision non-destructive testing (NDT), allowing for detailed visualization of fine defects and internal structures. Equipped with high-resolution detectors and optimized X-ray sources, the systems can accurately inspect bubbles, cracks, and foreign materials in metal components, electronic devices, and composite materials.

Thanks to cutting-edge 3D imaging capabilities, the systems generate detailed three-dimensional images, enabling precise dimensional measurements and defect analysis. These features contribute significantly to enhancing quality control and accelerating research and development processes.

Flexible X-Ray Source Options for Micro to Large-Scale Inspection

Nanofocus X-ray is suited for analyzing fine structures, microfocus is ideal for standard precision inspections, and high-voltage minifocus up to 450 kV is used for penetrating castings and high-density materials. This enables high-resolution visualization of internal structures ranging from electronic components to large metal products, providing optimal non-destructive testing tailored to various industrial applications.

Key Models of X-ray Radiography-Based 2D & 3D CT Scanning Systems

Small Part Measurement ( Electronic Components)

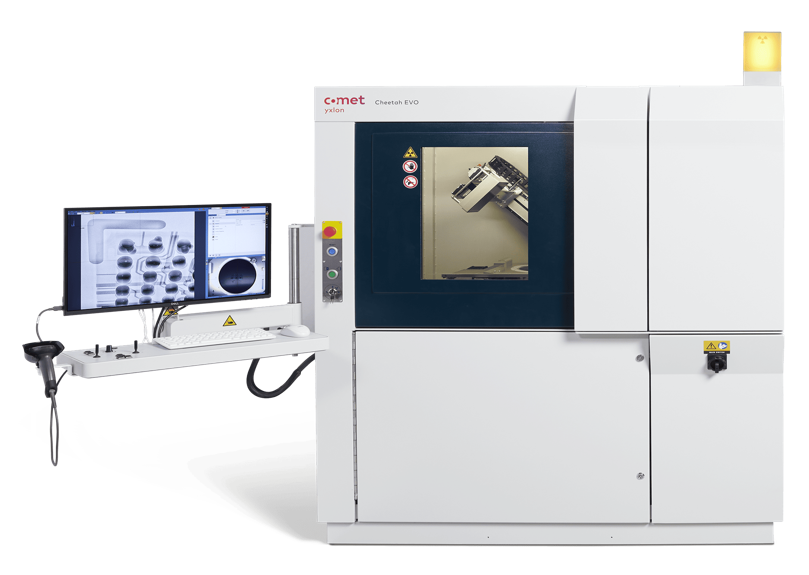

【Cheetah EVO】

・Output: 25–160 kV Multi-focus (Transmission Type)

・Main Applications: Electronic components, plastic parts, rubber parts, metal parts, etc.

・Features:

-Equipped with in-house developed X-ray tube supporting multiple modes: Nanofocus, Microfocus, and High-Power mode, enabling versatile applications.

【Cougar EVO】

・Output: 25–160 kV Multi-focus (Transmission Type)

・Main Applications: Electronic components, mounted circuit boards (PCBs), etc.

・Features:

-Compact design suitable for space-saving (1,100 x 1,050 mm footprint)

-Ideal for part analysis and inspection using microfocus imaging

Medium Part Measurement (Metal & Plastic Products)

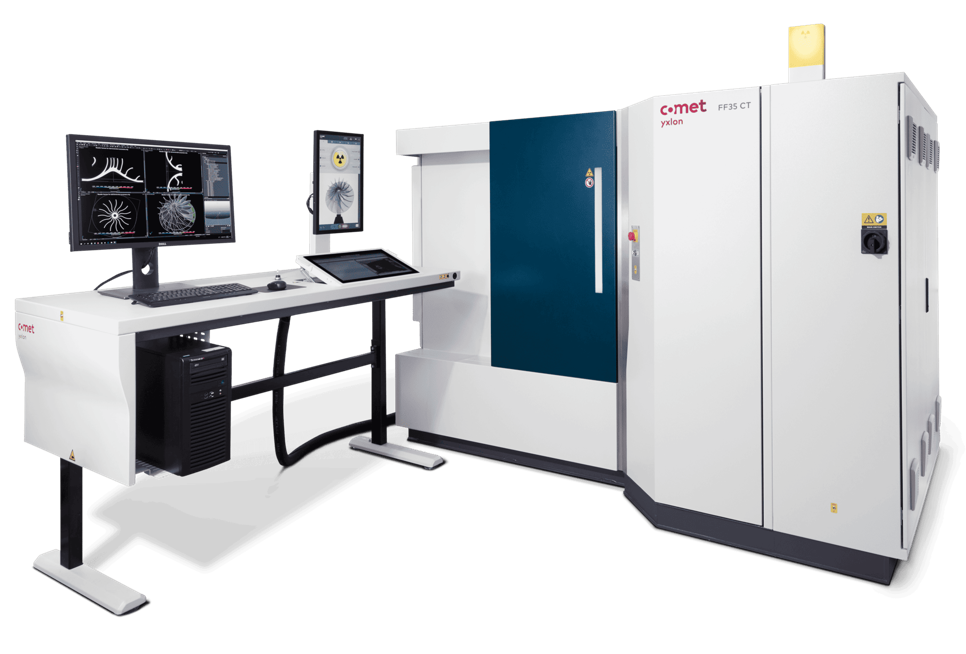

【FF35CT】

・Output: 225 kV Microfocus (Reflection Type), 190 kV Nanofocus (Transmission Type) optional

・Main Applications: Fine works such as CFRP, small electronic components, castings, etc.

・Features:

-Equipped with two types of X-ray tubes: 225 kV reflection type and optional 190 kV transmission type

-Dimensional measurement accuracy: 5.9 μm + L/75 [L in mm] (with CT measurement option)

-Helical CT option ideal for imaging layered materials

-Granite stage with low thermal expansion coefficient for enhanced stability

【FF20CT】

・Output: 190 kV Nanofocus (Transmission Type)

・Main Applications: Fine works such as CFRP, small electronic components, castings, etc.

・Features:

-Granite stage with low thermal expansion coefficient for enhanced stability

-Equipped with a high-resolution 190 kV microfocus transmission X-ray tube

-Dimensional measurement accuracy: 3.9 μm + L/75 [L in mm] (with CT measurement option)

Large Part Measurement (Engines & Castings)

【UX50】

・Output: 450 kV Minifocus

・Main Applications: Automotive, metal casting, additive manufacturing, composite modules, etc.

・Features:

-Line detector minimizes the impact of scattered X-rays for enhanced image clarity

-High-power 450 kV minifocus X-ray tube

-Supports two types of detectors: line detector and flat panel detector

【FF85CT】

・Output: 190 kV (Nanofocus), 225 kV / 300 kV (Microfocus), 450 kV (Mesofocus), 450 kV / 600 kV (Minifocus)

・Main Applications: Automotive and aerospace industries (engine parts, castings, composite modules, etc.)

・Features:

-Granite-base manipulator for low thermal expansion and enhanced stability

-Supports two types of X-ray tubes: minifocus and microfocus

-Equipped with two types of detectors: flat panel and line detector

Measurement from Small Metal Parts to Large Welded Components

【UX20】

・Output: 225 kV Mesofocus, 160 kV / 225 kV Minifocus

・Main Applications: Large castings and welded parts, small metal components, automotive parts, etc.

・Features:

-Semi-automated inspection enabled by simple programming

-Offers two X-ray tube voltage options: 160 kV and 225 kV

Easy Operation for All with Intuitive Geminy User Interface

The intuitive interface utilizes graphical symbols for easy visual operation, enabling fast and accurate inspections regardless of the operator’s skill level through automation features. Additionally, network connectivity and remote operation support streamline data management and analysis. This ensures improved productivity, consistent inspection accuracy, and enhanced quality control.

For details on compatible models, please contact us.

Contact Us for X-ray NDT CT Scanner Details and Inquiries

We offer solutions to the challenges you face on-site. Please feel free to contact us.