The comprehensive Digital Image Correlation (DIC) system, MatchID, is a powerful measurement and analysis tool that includes high-resolution imaging, real-time deformation tracking, strain analysis, material evaluation, numerical simulation, and vibration testing.

Ideal for new product development, CAE simulation validation, and material strength testing, MatchID enables high-resolution measurement of strain and stress in targeted areas without the need for complex optical setups.

Digital Image Correlation (DIC) MatchID Equipment | Cameras & Lenses

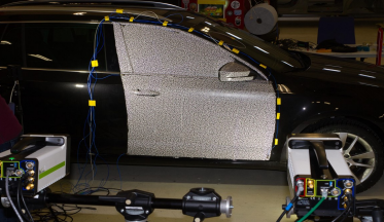

MatchID cameras seamlessly integrate with proprietary image acquisition software and support a variety of camera options synchronized through our proprietary Trigger Unit. For static tests requiring frame rates up to 100 frames per second (FPS), we collaborate with multiple camera providers to offer solutions tailored to your needs. High-quality lenses ensure clear image capture, which is critical for accurate DIC measurements. We carefully select optimal camera and lens combinations based on sensor coverage, optical distortion, viewing angle, ease of use, and image quality.

Digital Image Correlation (DIC) MatchID Equipment | Lighting

For quasi-static measurements (with capture speeds up to ~100 FPS), a lighting setup with 3000 lumens is sufficient to flexibly adjust imaging conditions. Conversely, high-speed camera applications or quasi-static setups with low exposure times require lighting systems with higher lumen output.

The lighting systems are designed with flexible output (light intensity) and beam angle options. For example, a narrow field of view may require a 15° beam angle, whereas larger structures may need a wider 60° beam angle. The proposed lighting system allows for easy adjustment by changing filters according to the field of view (i.e., the size of the object being analyzed with DIC), eliminating the need to purchase multiple lighting units. Additionally, to reduce specular reflections, linear light polarizing filters are available and can be used in combination with lens-specific filters.

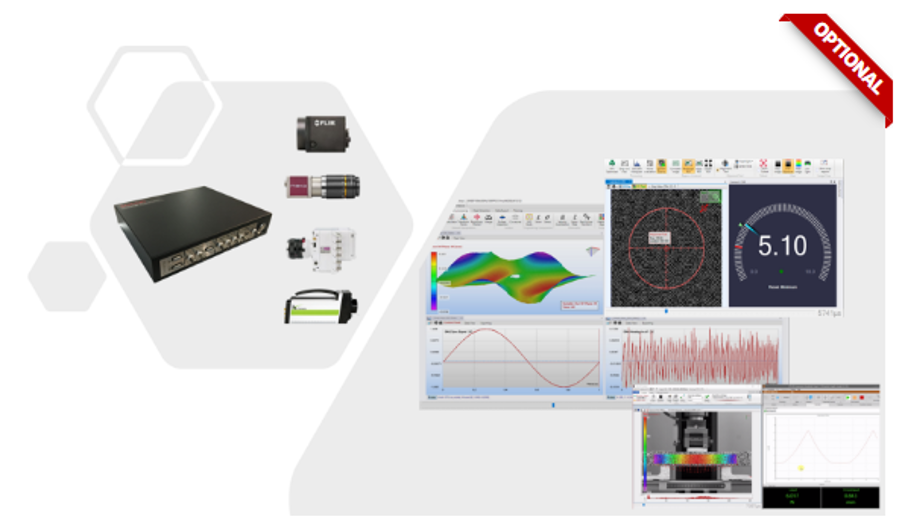

Digital Image Correlation (DIC) MatchID Equipment | MatchID Unit

The MatchID Unit plays a vital role in ensuring precise DIC measurements. It synchronizes image acquisition timing and analog signals with high precision, preventing failures in data capture. The Unit features a universal interface compatible with all supported cameras and includes a trigger mechanism. It also provides synchronization signals for external devices, maintaining timing accuracy throughout the measurement process.

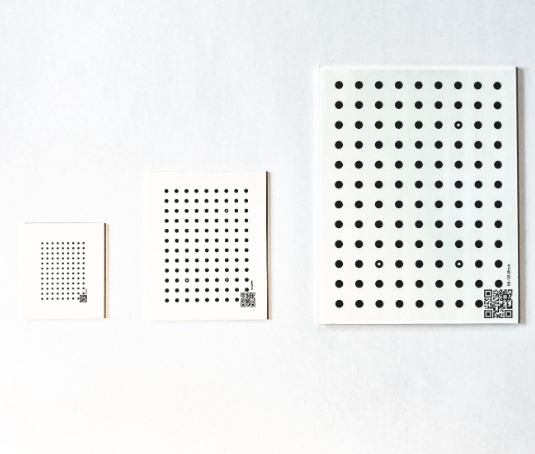

Digital Image Correlation (DIC) MatchID Equipment | Calibration Targets

Accurate DIC analysis depends on the quality of calibration targets, which correct distortions from lenses and sensor alignments. Our calibration targets are carefully manufactured for precision in strain and displacement measurement. Depending on your testing environment, we offer various target sizes and patterns, suitable for thermal chambers, high-temperature conditions, and different scales—from small fields of view to large structural tests.

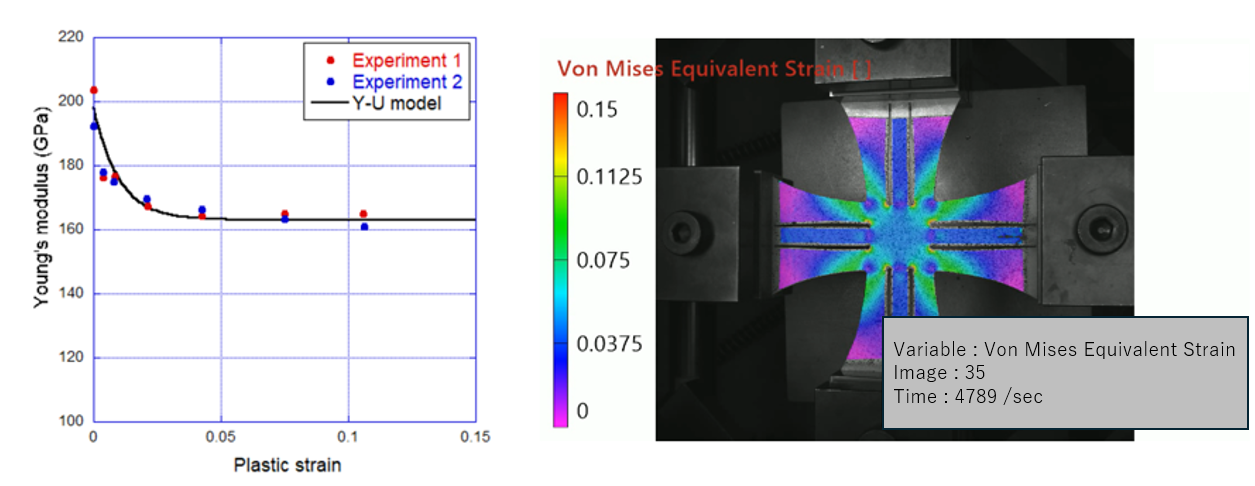

Case Study: Visualization of Shear Strain Distribution Using DIC

We present a case study in which DIC was used to visualize shear strain distribution for the purpose of validating forming theories.

Nagano Prefectural Institute of Industrial Technology – Abstract

“In the advancement of precision press forming, understanding the shear processing mechanism is of great importance. Although numerous studies have been conducted on shear processing, experimental validation remains limited. Therefore, to verify the mechanism through visualization of material strain states, we performed DIC-based strain measurements using a specially prepared half-split die that allowed cross-sectional observation during processing. As a result, the observed shear strain distribution confirmed that the deformation behavior followed theoretical forming principles.”

Full article available here:

https://www.gitc.pref.nagano.lg.jp/reports/pdf/R6/R06P49_P51.pdf

Learn More About DIC

We provide detailed documentation including measurement accuracy specifications. For product inquiries or questions about our services, please contact us.