Experiments

Smart & Easy Machine Vision Camera Control Software | QS-Grabber

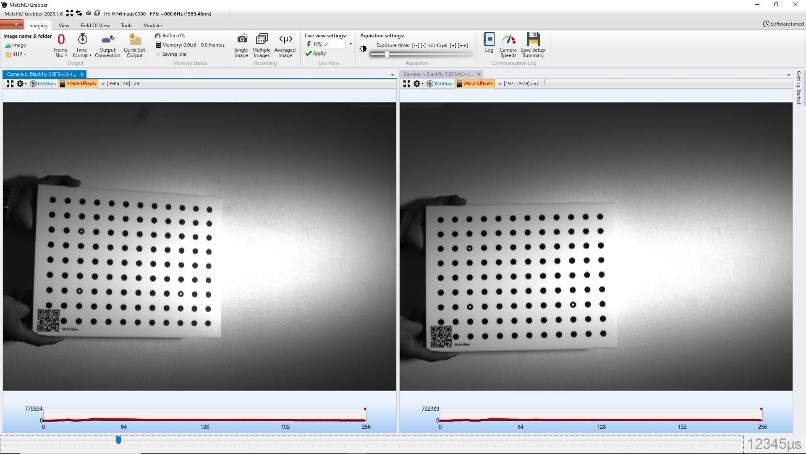

QS-Grabber is software for controlling machine vision cameras. It allows easy setup of experiments, from focusing on the subject to checking the lighting conditions. In LIVE View mode, the strain distribution during shooting can also be visualized. Analog data during experiments is synchronized with camera shooting and immediately output as analyzable data in MatchID STEREO. MatchID’s shooting software supports many camera models. For supported models, please contact us.

Efficient Data Handling for High-Speed Cameras | HS-Grabber

HS-Grabber is software for controlling high-speed cameras. It allows easy setup of experiments, from focusing on the subject to setting exposure times for high-speed shooting. Additionally, it converts and outputs the large volumes of data captured into analyzable data for immediate DIC analysis in MatchID STEREO. This enables instant DIC analysis. The shooting software supports many high-speed camera models. For supported models, please contact us.

Analysis

Advanced Strain & Displacement Tools | MatchID STEREO

Using the imaging data obtained from two cameras and high-precision calibration results, MatchID STEREO visualizes strain and displacement through analysis. This system supports various tests involving out-of-plane deformation. Additionally, by selecting constitutive equations, stress calculations can be performed, making mechanism analysis smoother. It supports everything from black-box analysis with default settings to high-precision analysis with detailed user settings.

Optimized Correlation for User Needs | MatchID 2D

Perform correlation of single camera data to analyze planar deformation. Calibration data is not required. Other than that, correlation can be customized to meet user needs.

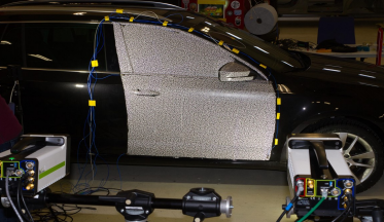

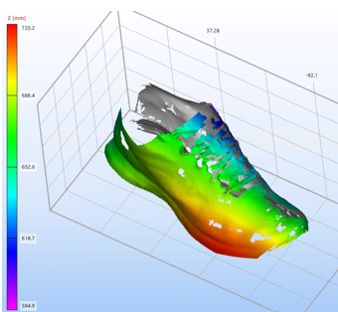

DIC Technology for 3D Data Visualization | MatchID MULTI

By analyzing data from three or more cameras, true 3D visualization can be achieved. After analyzing the data from each camera within the space, it can be synthesized in a 3D space for visualization. Utilize advanced DIC technology for enhanced results.

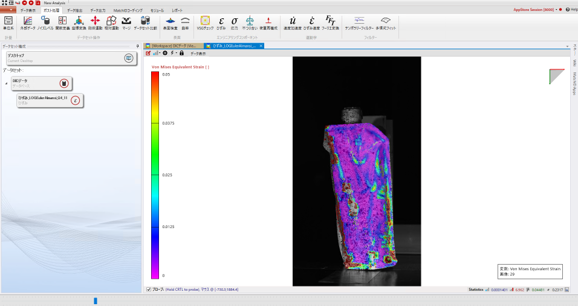

Flexible Visualization for Measurement Data | MatchID Results Viewer

The MatchID Results Viewer comes with a flexible results viewer and data analysis package integrated by default.

It offers:

- Correlation Results: Visualization of displacement, strain, strain rates, velocities, accelerations, and stress reconstruction to meet user needs.

- Advanced Functions: Includes vibration cancellation, coordinate transformation, surface inspection, curvature FFT, and modal analysis tools.

- Data Export: Supports exporting visualization data in various formats (.csv, .mat, .bmp, .avi, .mp4).

- Sharing Capabilities: Allows sharing visualization data with users who do not have a license.

- Customization: Advanced users can perform coding and develop custom applications.

Post₋Processing

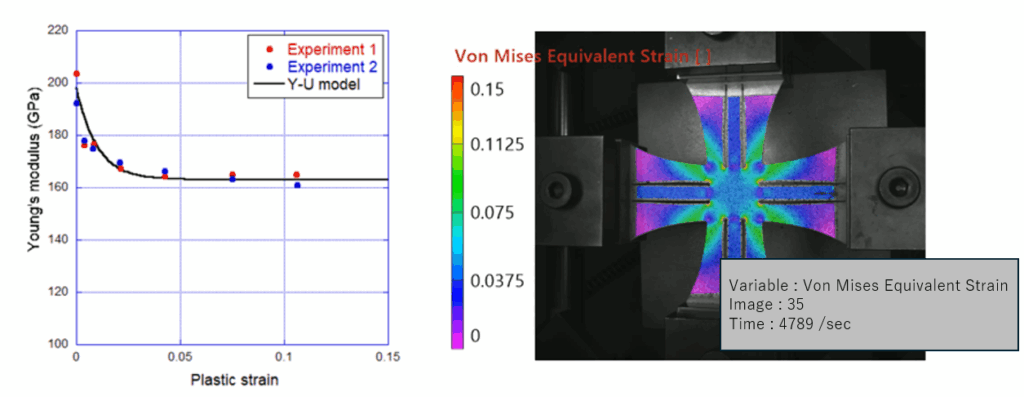

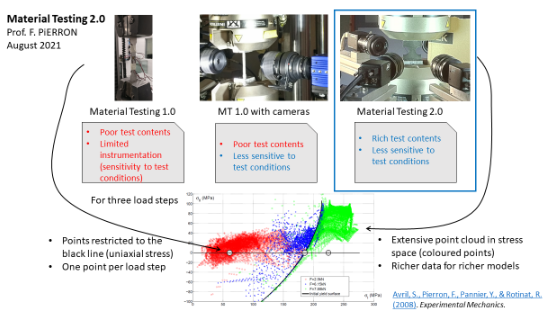

Material Parameter Identification | VFM (Virtual Fields Method)

MatchID incorporates the VFM (Virtual Fields Method) for identifying material parameters. This allows for the identification of parameters related to most types of material behavior across various material models. Unlike typical existing methodologies, VFM can be applied to much more complex material models, providing highly accurate results in a short time. Try VFM combined with high-end DIC for enhanced results.

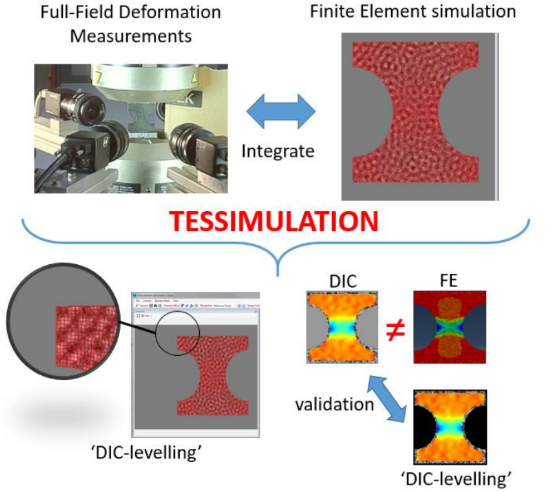

Comparison of Digital Image Correlation (DIC) and Finite Element (FE) Simulation | FEVAL

Validating simulations against experimental tests is a universal challenge in engineering. In particular, accurately comparing results from Digital Image Correlation (DIC) with those from Finite Element (FE) simulations has remained a persistent issue.

To address this, the system incorporates the FEVAL module, designed specifically for the validation of structural CAE results. By aligning the measurement data with the simulation outputs and unifying the mesh resolution, the module establishes a one-to-one correspondence between experimental and simulated data. This process enables accurate full-field comparisons across the entire region of interest.

By eliminating discrepancies in spatial alignment and data structure, this approach provides a true digital twin and contributes to the reliable validation of structural material behavior.

Technical Information on Digital Image Correlation (DIC)

Case Study by Nagano Prefecture Industrial Technology Center

We present a research note showcasing the validation of forming theories through visualization of strain distribution during shear deformation using MatchID.

https://www.gitc.pref.nagano.lg.jp/reports/pdf/R6/R06P49_P51.pdf

Inquiries and Other Information of Digital Image Correlation

We have prepared materials detailing the specifications, including measurement accuracy. Please feel free to contact us with any questions about our products or services.