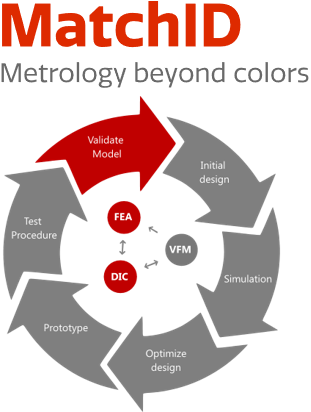

MatchID is a comprehensive Digital Image Correlation (DIC) system designed to provide precise measurement and analysis tools. It supports high-resolution imaging, real-time deformation tracking, strain analysis, material characterization, numerical simulation, and biaxial testing.

It is an ideal solution for new product development, CAE simulation validation, and material strength testing. Without the need for complex optical setups, MatchID enables high-resolution measurement of strain and stress in targeted areas, precisely meeting your testing requirements.

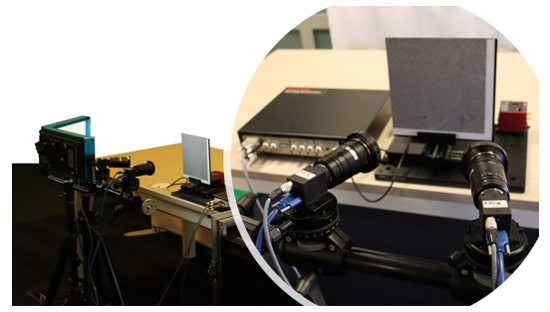

Flexible Setup for Precise Phenomenon Capture

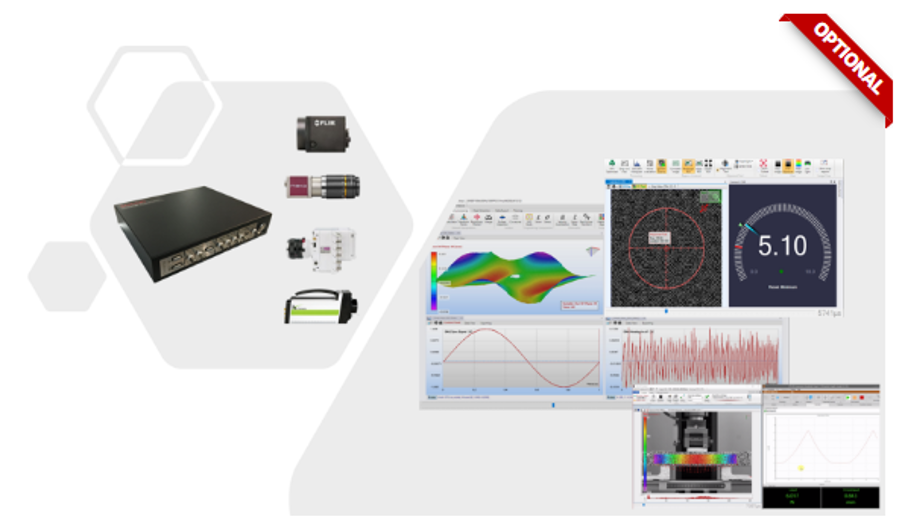

MatchID is not only a software platform but also integrates seamlessly with a variety of hardware solutions tailored to different applications. Its flexible setup options allow for customized configurations that deliver new levels of visualization to meet your specific needs.

Basic

To enhance the accuracy of DIC measurements, we offer dedicated software and professional training.

We have also developed optimized solutions for cameras, lenses, filters, lighting, optical rail systems, and computers – ensuring that every component works together to support the success of your testing.

Advanced & Customization Edition

MatchID enables high-performance imaging using high-speed and infrared cameras.

It will help uncover complex things and reveal behaviors that were previously unobservable.

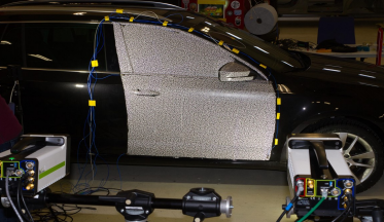

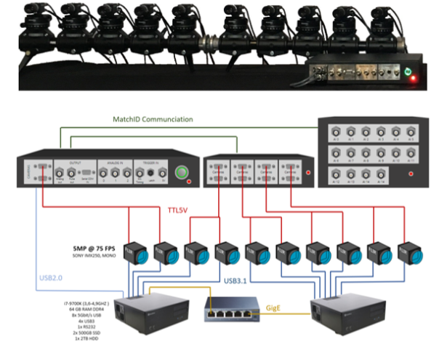

We offer a multi-camera system capable of 360-degree and large-scale measurements. With a breakout unit, full camera synchronization is possible, allowing the system to be expanded to multi-camera configurations.

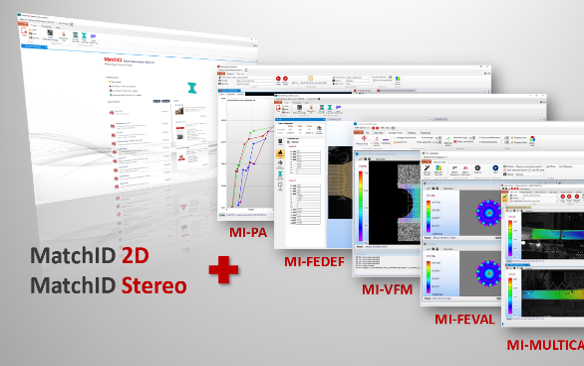

Software for Image Acquisition, DIC Analysis, and Proprietary Modules

MatchID adopts a modular structure centered around image analysis software. It supports importing images from any source, allowing you to determine optimal settings and measurement accuracy using standard modules and perform analysis with Digital Image Correlation (DIC). Additionally, it offers image acquisition and post-processing modules. The system is available under both rental and purchase options.

Experiments:Optimized Tools Compatible with a Wide Range of Cameras

We provide optimized tools for experimental image acquisition that are compatible with a wide range of cameras.

Using the MatchID Trigger Unit, camera synchronization is achieved, while analog experimental data can be captured through an NI-USB device. The system also includes helpful tools such as live histograms and overexposure indicators to assist in experimental setup, enabling real-time measurements.

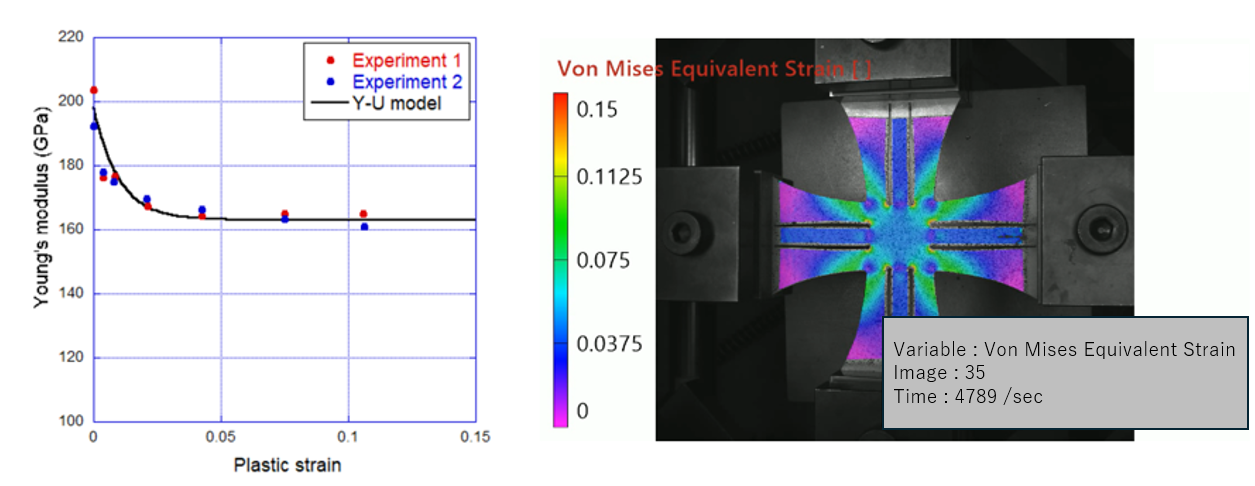

Analysis: Result analysis with stress conversion capabilities

Each module is designed to meet specific experimental and analytical needs.

For example, 2D DIC is ideal for basic in-plane tests, while Stereo DIC supports advanced analysis involving out-of-plane motion.

Multi-DIC enables full 360° capture using data from multiple cameras.

In addition, standard features include an integrated results viewer and data analysis tools capable of stress conversion

Post-Processing: Seamless handling of measurement data

The Virtual Field Method (VFM) seamlessly identifies material model parameters using full-field measurement data.

In addition, FEVAL (Finite Element Validation) processes FEA simulation results using the same filters applied to experimental data, ensuring accurate comparisons.

With MatchID’s proprietary post-processing capabilities, a true digital twin is achieved. Both methods support batch-mode processing for enhanced efficiency.

Applications

- Vibration

- High-Speed Camera (Pouch Drop Test)

- Infrared Camera (Temperature Measurement)

- Marker-Based Motion Tracking

- Clamping of Pressed Components

- Surface Strain

Related Technologies in Digital Image Correlation

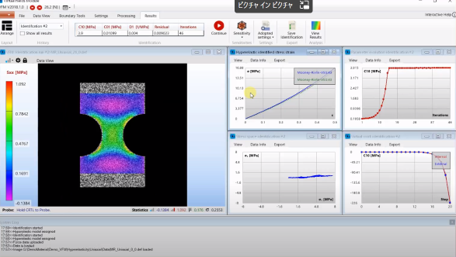

Case Study: Nagano Prefectural Institute of Industrial Technology

We introduce a research note detailing the verification of forming theory through visualization of strain distribution during shear, using MatchID.

https://www.gitc.pref.nagano.lg.jp/reports/pdf/R6/R06P49_P51.pdf

Learn More About DIC

We provide detailed documentation, including specifications such as measurement accuracy.

If you have any questions about our products or services, please do not hesitate to contact us.