Mission

Many companies in the aerospace industry around the world always have the following common issues and requests for improvement. *

- Foresee problems in the assembly process

- Compare product data and drawing data

- Shorten the response time

- Improve the manufacturing process

Especially for 1, many of the various parts needed to manufacture aircraft are manufactured in different factories. For example, before actually assembling the wings and fuselage, you can’t see if they really fit. Many companies wish to foresee in advance problems that are discovered by actually assembling parts, as well as wing / body coupling.

Solution

The numerical and dimensional data acquired from measuring machines, etc. are integrated and managed, enabling the person who wants to see fresh data to check at the angle he wants to see and solves problems.

Proposal Contents

ATS CM4D is a system that bridges the gap between the virtual world of computer-aided design in the aerospace industry and the physical world of manufacturing, and the scale and scope of ATS CM4D projects in the aerospace industry vary widely from company to company. But generally includes the following requirements:

- Receive data in multiple formats from multiple measuring instruments

- Convert data to a standard format for integration into a single database

- Create reports that can be accessed from anywhere and used to improve products and processes and require rapid analysis

Also, conventional SPC alone could not predict problems that could occur in the assembly process. By incorporating product quality validation, which is a product-centric approach, assembly can be simulated by virtual assembly and virtual shimming even if the parts to be assembled are located many kilometers away. Therefore, it is possible to quickly understand the problem and take countermeasures before shipping. As a result, not only the machine but also the operator’s valuable man-hours can be greatly reduced.

[ATS CM4D introduction effect in aerospace industry]

- Improve internal and supply chain communication and coordination

- Improved manufacturing processes thanks to up-to-the-minute informed decisions

- Reduce machine and operator operation time for faster numerical and dimensional inspection

- All numerical and dimensional data are recorded and analyzed in one place, reducing training and maintenance costs

System Configuration

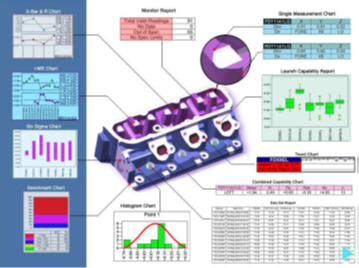

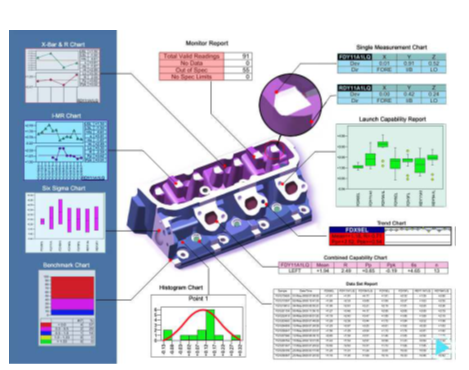

System Image

Assembly process which requires a huge volume of production costs of humans and machines.

Sample of a report of product quality inspection result