Eliminate Rework and Accelerate Workflows with Instant, On-site Component Measurement and Analysis.

REGALIS Go! is a specialized software solution for bridge component inspection and pre-assembly simulation. It can import AutoCAD data exported from any 3D full-scale measurement system, enabling immediate on-site component measurement and analysis to eliminate rework. Inspection reports can also be generated automatically. By leveraging high-precision 3D measurement data, REGALIS Go! enables highly accurate 3D pre-assembly simulations.

The Key to Streamlining Bridge Measurement and Pre-Assembly

“Our long-term objective is to eliminate all yard-based pre-assembly operations.”

We heard this need directly from bridge manufacturers—it was their most pressing challenge.

REGALIS Go! was engineered by reverse-designing from this ultimate objective. Purpose-built for bridge production, it provides advanced measurement support and highly accurate pre-assembly simulation.

By utilizing high-precision 3D measurement data and shifting physical operations into a digital environment, REGALIS Go! delivers a step-change in productivity.

| Item | Without REGALIS Go! | With REGALIS Go! |

| Measurement Personnel | Two staff members required for on-site measurement, plus one additional staff member at the office for report preparation. | Measurement can be performed by a single operator. |

| Workflow | After on-site measurement, staff must return to the office to create inspection reports. | The entire process—from measurement to analysis and automated report generation—can be completed on-site. |

Product Concept and Core Functionalities

REGALIS Go! is founded on three core principles that prioritize ease of use in real-world operations.

User-Friendly Operation

Designed for intuitive use by anyone, REGALIS Go! features a user interface optimized for tablet operation.

Even without specialized expertise, users can perform measurement and analysis tasks smoothly and efficiently.

Flexible Data Connectivity

Conduct measurements on a portable tablet in the field and perform in-depth analysis on a large desktop screen back at the office. REGALIS Go! delivers a seamless, location-independent workflow—from creating measurement routines to analyzing data.

Breakthrough Efficiency in Pre-Assembly Operations

By leveraging high-precision measurement data for virtual pre-assembly simulation, REGALIS Go! aims to significantly reduce—or even completely eliminate—the need for physical pre-assembly work in expansive and costly yard environments.

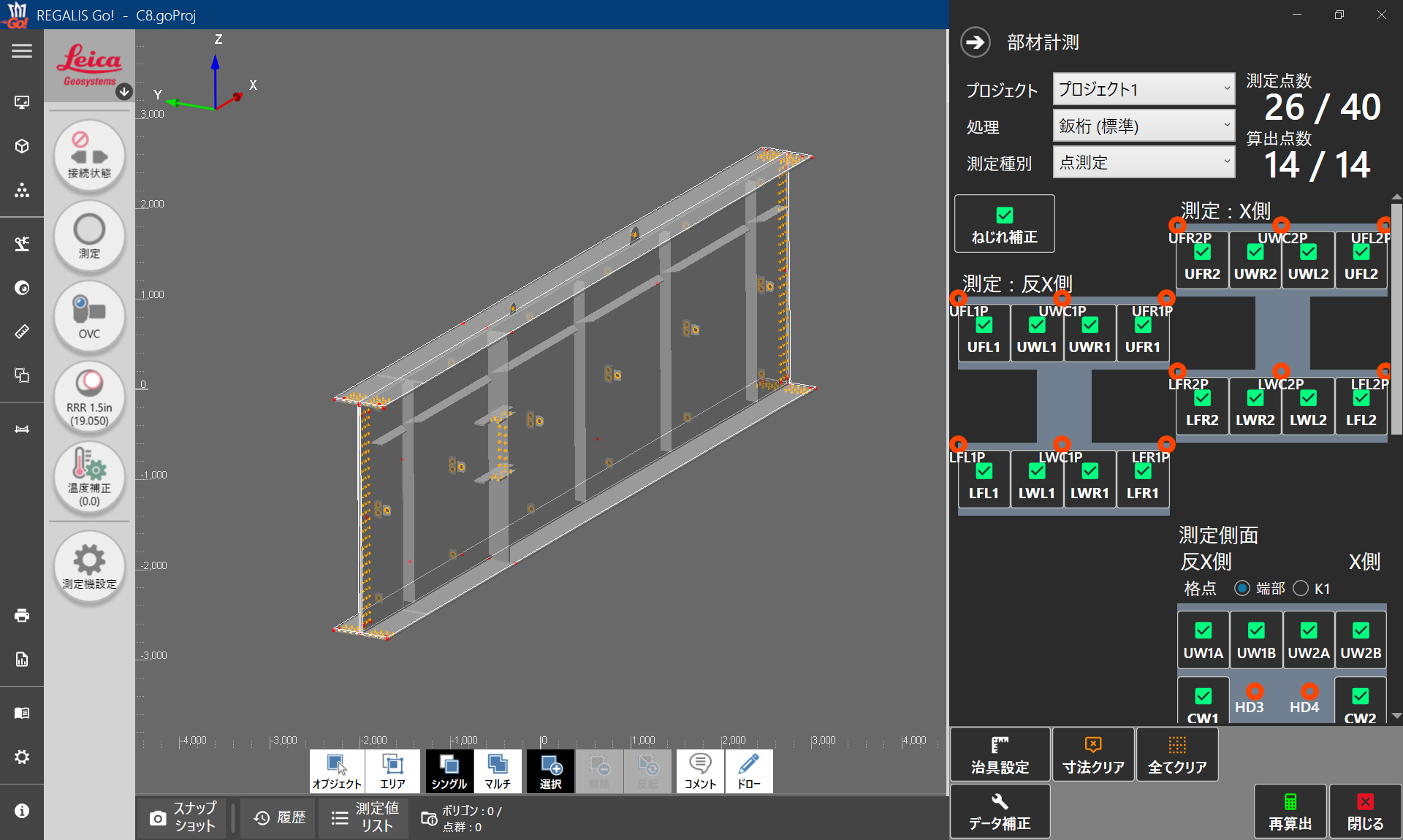

Features of the Bridge Measurement Support System

- Utilization of AutoCAD data exported from 3D full-scale measurement systems

- High-precision measurement using dedicated jigs, enabling improved measurement efficiency

- Measurement functions for primary girders such as plate girders and box girders

- Measurement functions for secondary components such as cross beams, lateral bracing, and sway bracing (bolt hole position measurement), including twist correction

- Automatic generation of inspection reports

- Immediate on-site analysis with no rework required

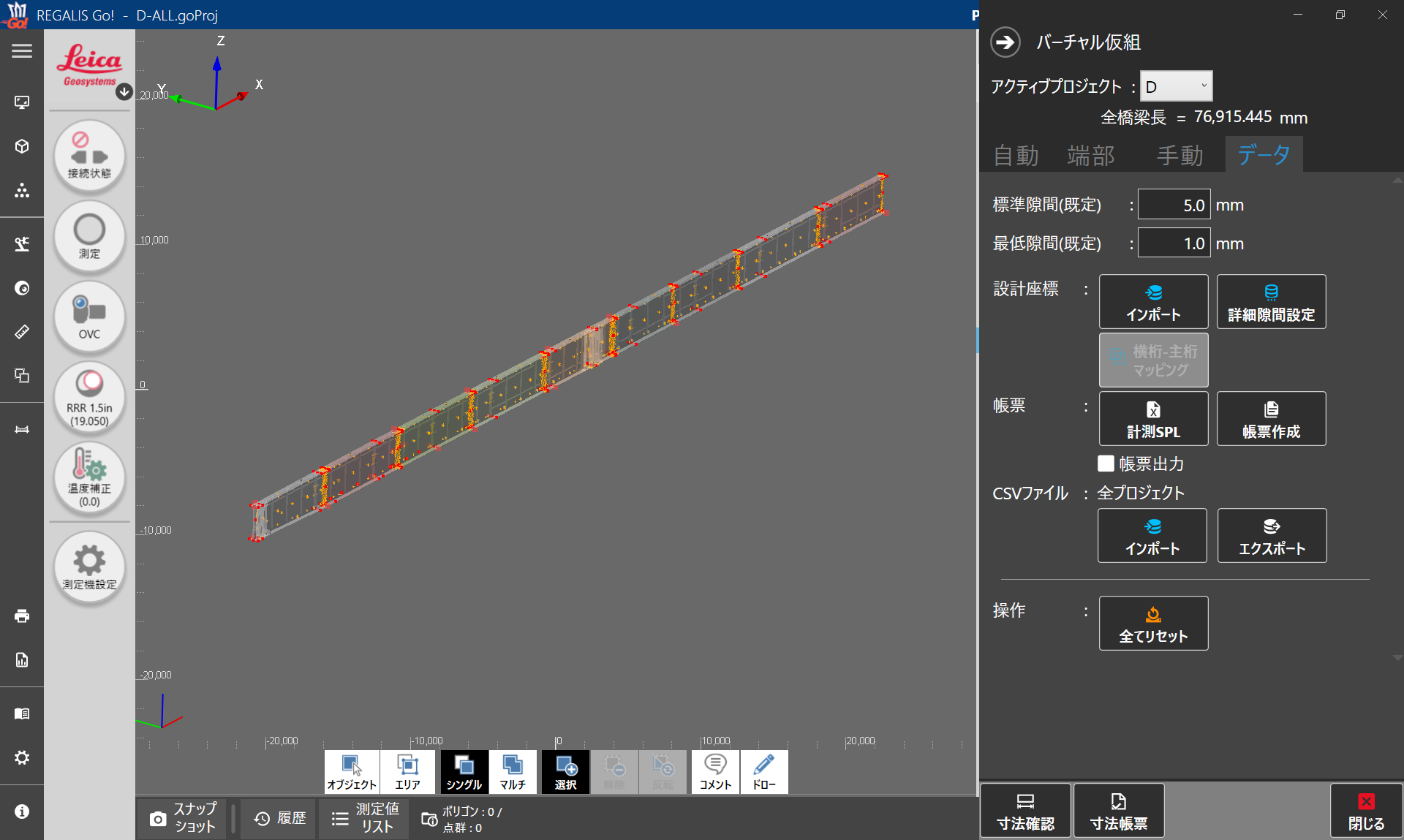

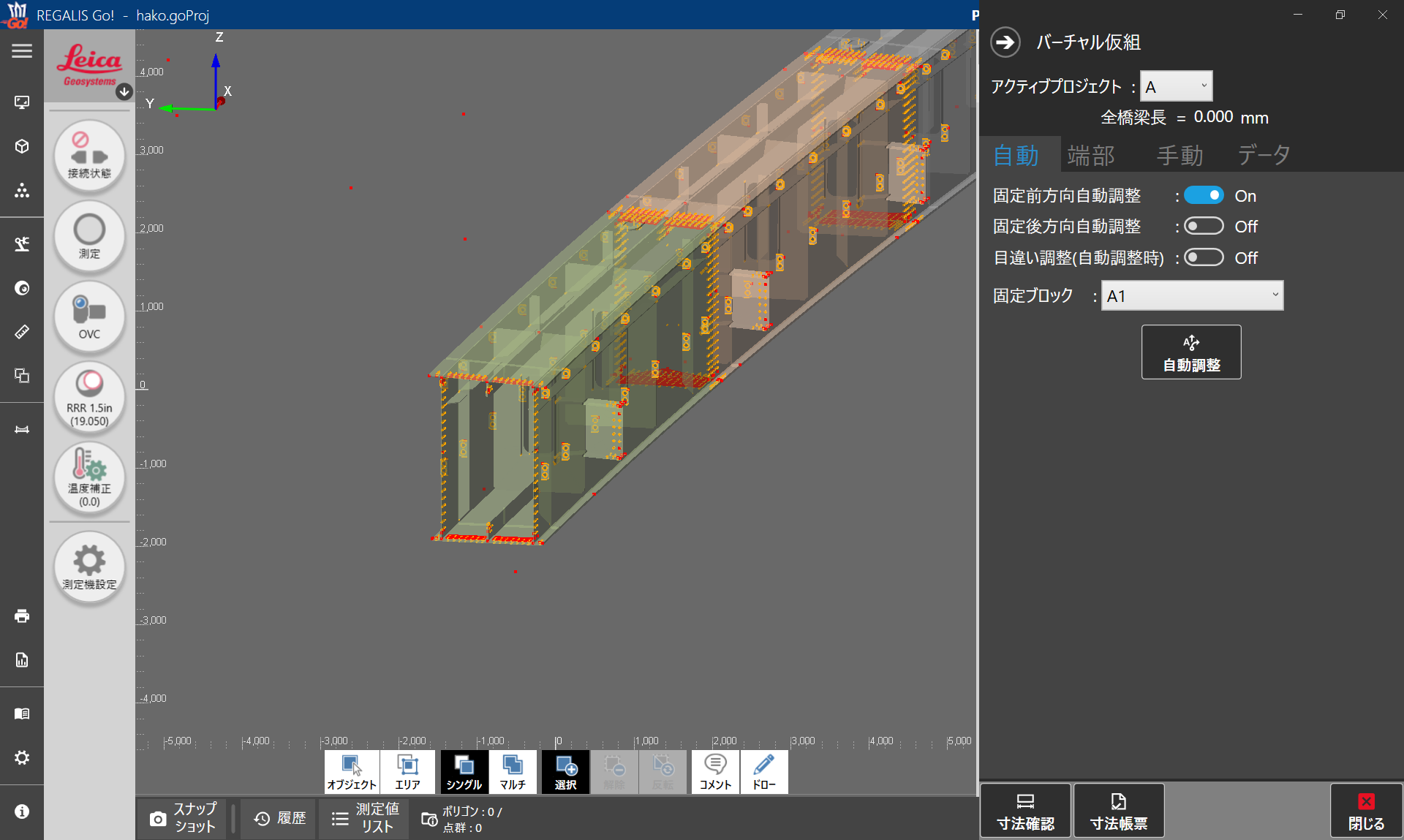

Key Features of the Pre-Assembly Simulation

- Utilization of AutoCAD data exported from 3D full-scale measurement systems

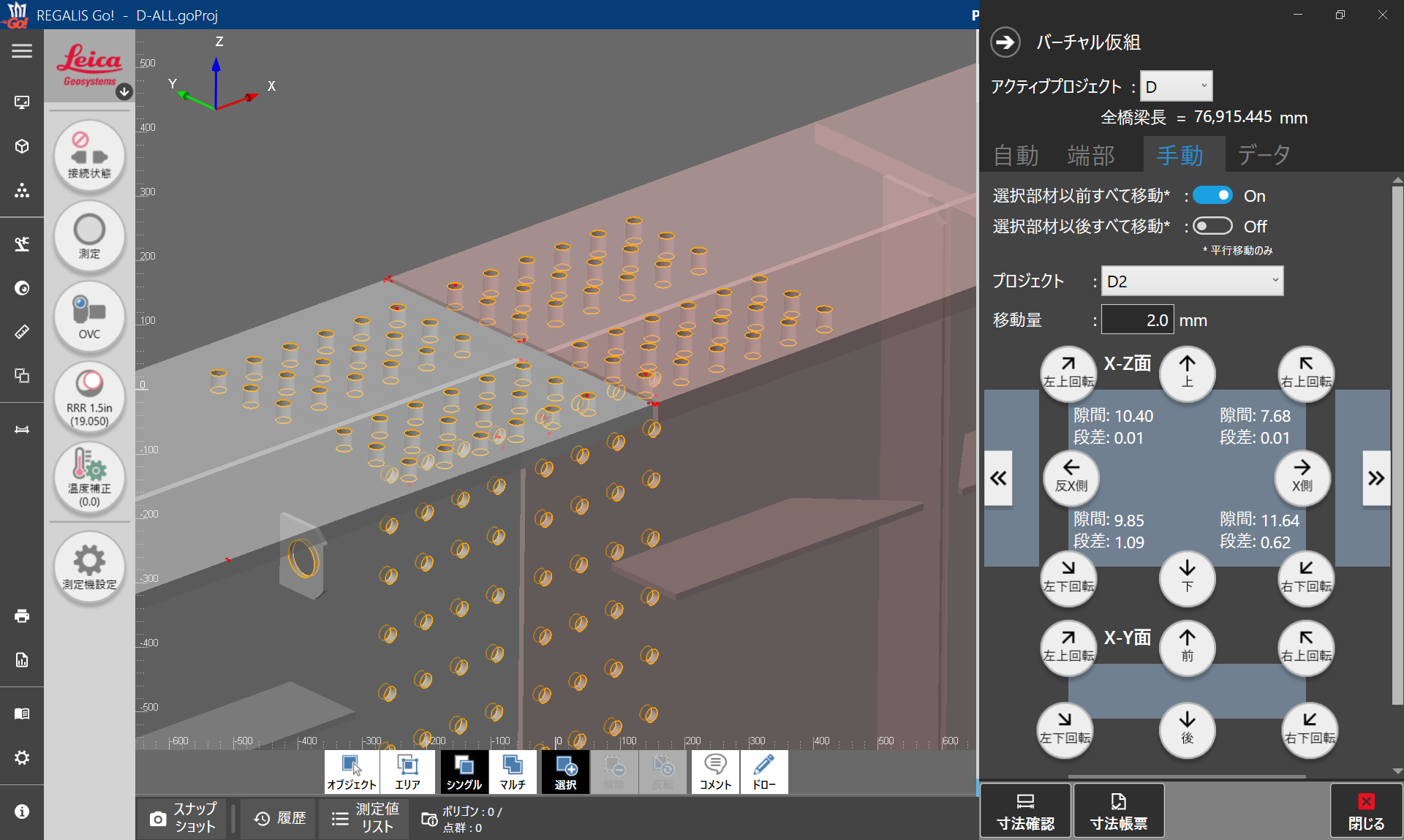

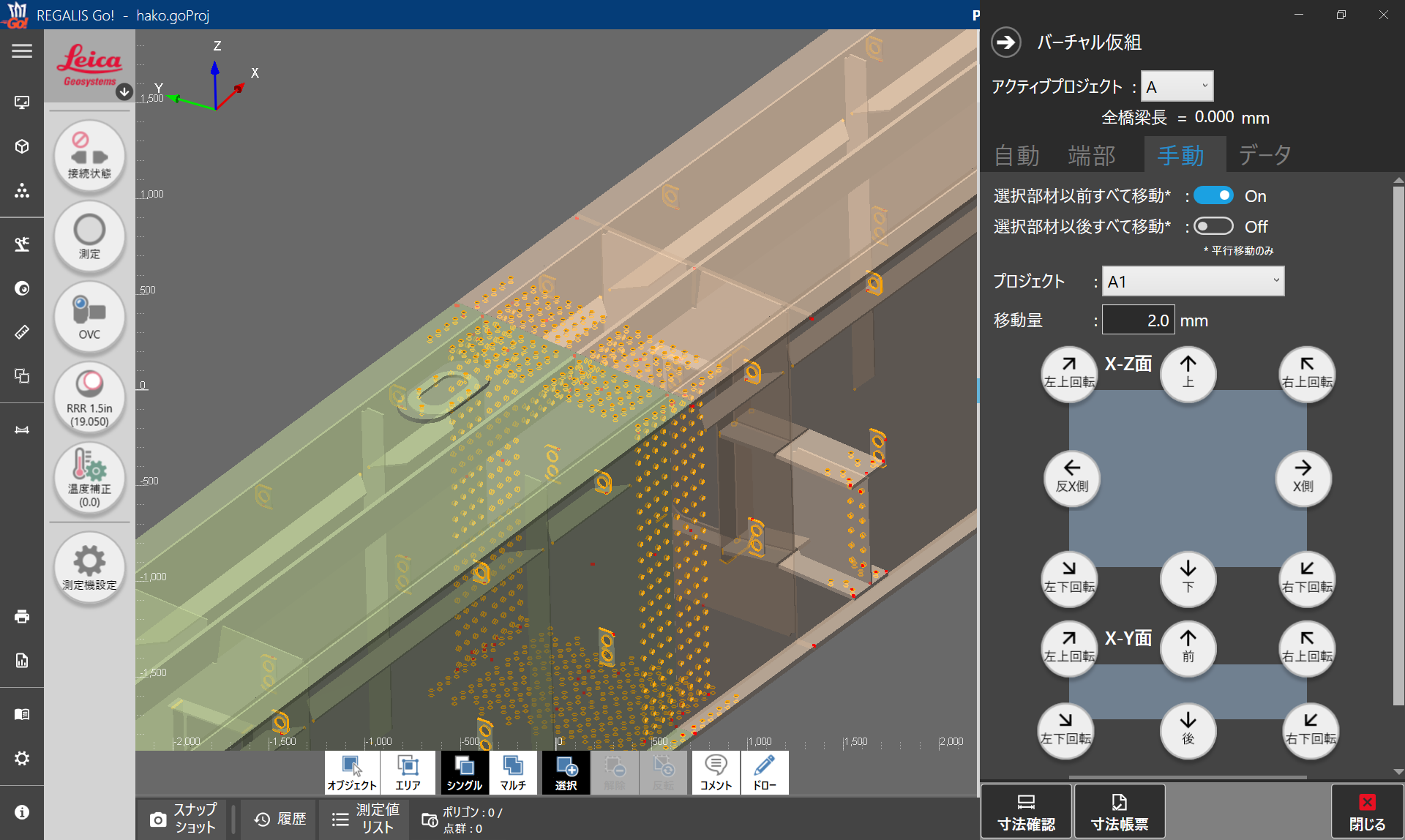

- Automatic and manual adjustment functions for pre-assembly component data

- Block-end adjustment functionality

- On-screen dimensional verification tools

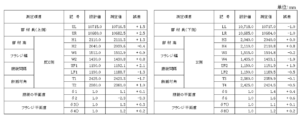

- Output of dimensional reports based on pre-assembly simulation results

- Measurement output for key parameters, including:

- Total length

- Span length

- Distance between main girder centerlines

- Plan diagonal length

- Main girder camber

- Girder rotation about the bridge axis

- Girder verticality

- Field joint gaps

- Girder alignment deviation

- Girder straightness

- Dimensional report generation for individual plate girder and box girder blocks

- Pre-assembly simulation functions for plate girders, cross beams, lateral bracing, and sway bracing

- Pre-assembly simulation functions for box girders, cross beams, lateral bracing, and sway bracing

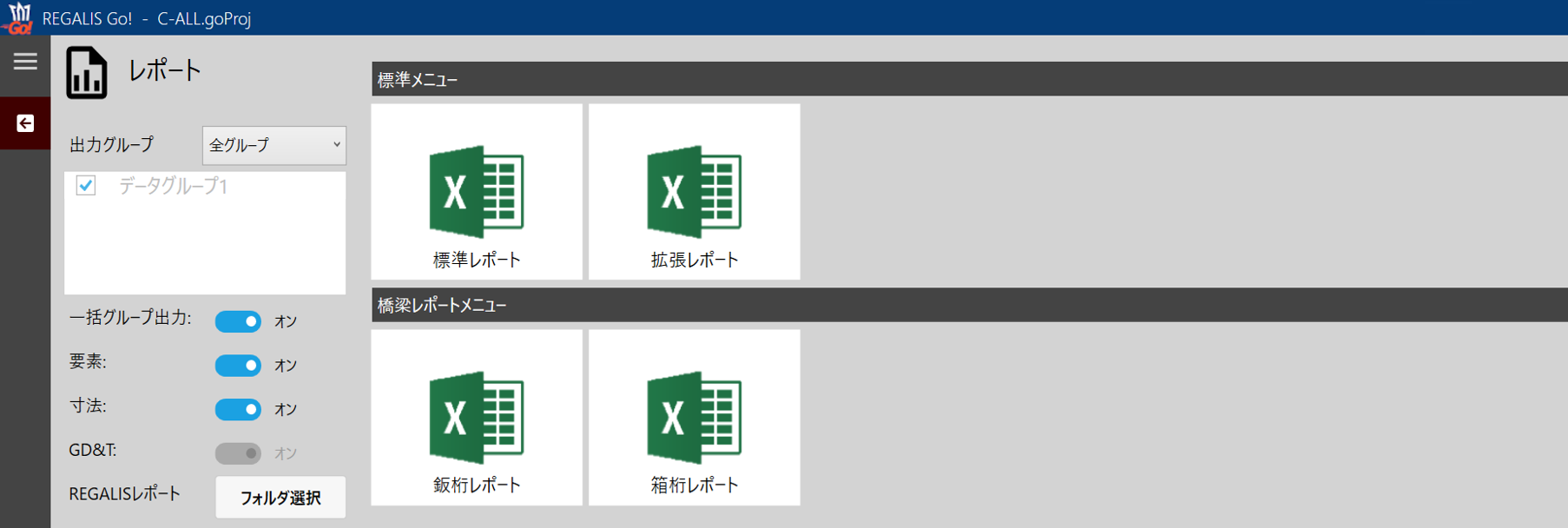

Dedicated Reporting and Documentation Output for Bridge Measurement and Pre-Assembly

REGALIS Go! provides advanced reporting capabilities that only this system can deliver.

Measurement results and deviations from design values can be exported in an easy-to-understand Excel format directly from the field.

Plate Girder Inspection Report

Box Girder Inspection Report

Pre-Assembly Simulation Report Generation

Acquiring 3D Measurement Data for Bridge Inspection and Pre-assembly

Core Technology Enabling High-Precision Measurement

To maximize the performance of REGALIS Go!, we rely on the Leica Absolute Tracker AT960, a world-leading device with an exceptional global market share. Its advanced technology enables highly reliable data acquisition in demanding bridge fabrication environments.

- The AT960 covers an expansive measuring range with a maximum diameter of 160 meters, minimizing the need to relocate the tracker—even when measuring large structural components.

- Its battery-powered, wireless design provides outstanding portability, allowing the system to be deployed anywhere on site.

- Because leveling is not required, precise measurements can begin immediately after setup—even on uneven, sloped, or unstable surfaces.

- For outdoor work environments where measurement beams are frequently obstructed, the AT960 features PowerLock, an automatic re-lock function that reacquires the reflector instantly, reducing interruptions and maintaining workflow efficiency.

Whether for REGALIS Go! component inspection, pre-assembly simulation, or broader measurement needs, we will recommend the ideal laser tracker from our comprehensive lineup of five models.

We invite you to experience this solution firsthand and see how it can help address your operational challenges.

If you are interested in benchmark measurements using your own workpieces or would like to request a product demonstration, please feel free to contact us.