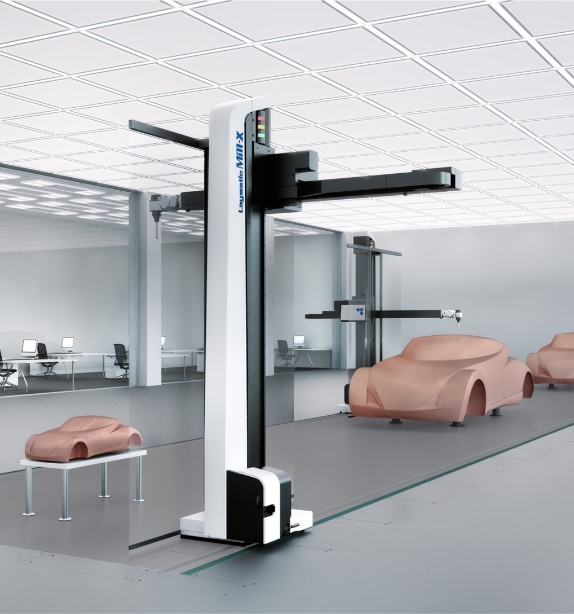

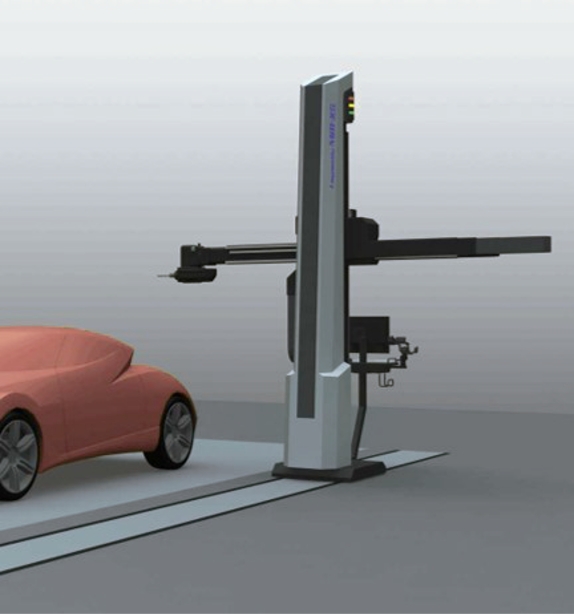

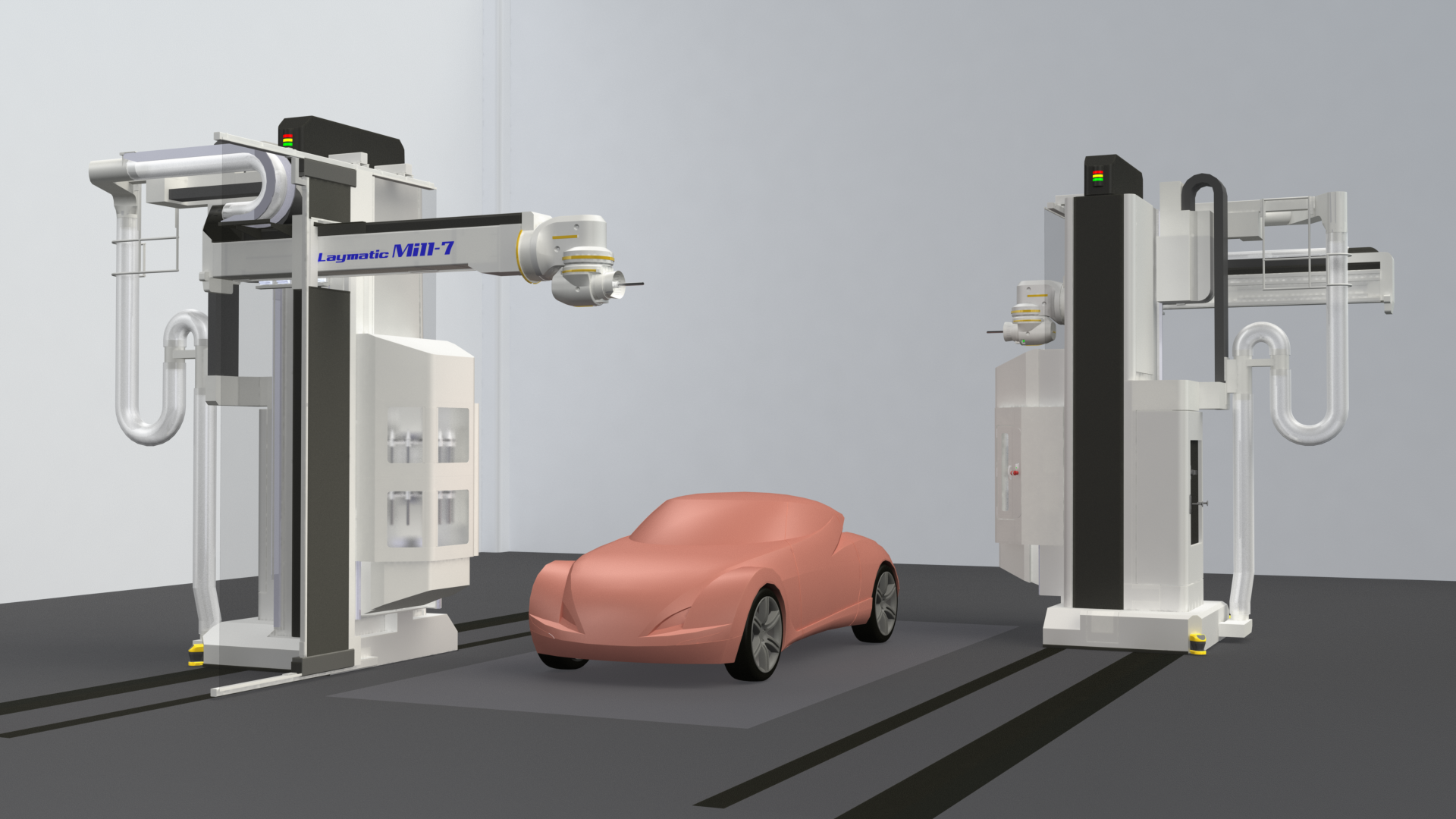

Laymatic Mill-7 is an all-in-one milling center equipped with simultaneous 5-axis milling, an automatic tool changer (ATC), and a dust collection system. It supports a wide range of materials, from initial prototype models to master models. With functions that enable unattended operation during nights and holidays, it contributes to higher productivity and reduced labor requirements.

Power and precision for master model milling

With a feed rate of 15 m/min, a spindle speed of 24,000 min⁻¹, and a highly rigid structure, Laymatic Mill-7 delivers high-speed, high-quality milling—even for hard resin materials.

Dust collection function for reduced cleaning time

The milling head is equipped with an integrated dust collection port, enabling processing while collecting airborne dust from foam and resin materials. This helps reduce cleaning time after milling and also contributes to minimizing dust inhalation by the operator.

Nighttime and holiday machining with ATC and safety features

The machine is equipped with an ATC, enabling unmanned operation from roughing to finishing by automatically changing tools. During unattended operation, collision and other accidents are prevented through opposing machine monitoring and sensors.

Speed, Spindle Speed, Milling Area

| Speed | 15m/min | |

|---|---|---|

| Spindle Speed | 24,000min⁻¹ | |

| Milling Area (Stroke lower limit: 160 mm) | 1,650mm(max) ✖ 2,800mm(max) ✖ 16,000mm | |