- Mission

-

Efficiency by automating assembly of large workpieces to reduce costs and solve the labor shortage.

Solution

The Leica Laser Tracker AT960 system supports a variety of automation applications. By automating, the measurement process time and cost can be reduced.

Proposal Contents

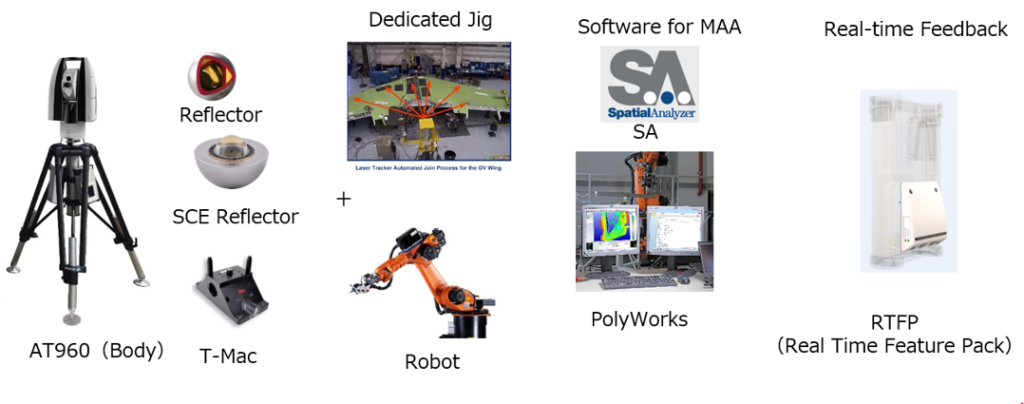

Leica Laser Tracker AT960(SR)/MR/LR/XR +Reflector+T-Mac + software(SA、PolyWorks, etc.)

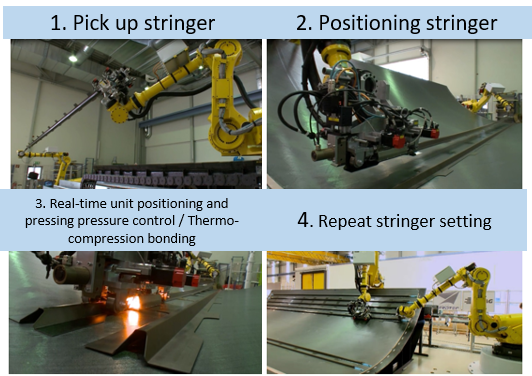

The automatic assembly system using the Leica Laser Tracker AT960 system is a six-degree-of-freedom measurement using a reflector or a six-degree-of-freedom (X, Y, Z, I, J, K, position and orientation information in space) detection unit (T -Mac) is a system that is attached to a general-purpose industrial robot and performs real-time feedback control of the tip position and posture of the robot at high speed and high accuracy.

It is an epoch-making system that can greatly reduce costs and save labor for conventional assembly using dedicated machines and assembly with human intervention. Many systems have been installed in Boeing and Airbus, contributing to improved production efficiency.

System Configuration

System Image

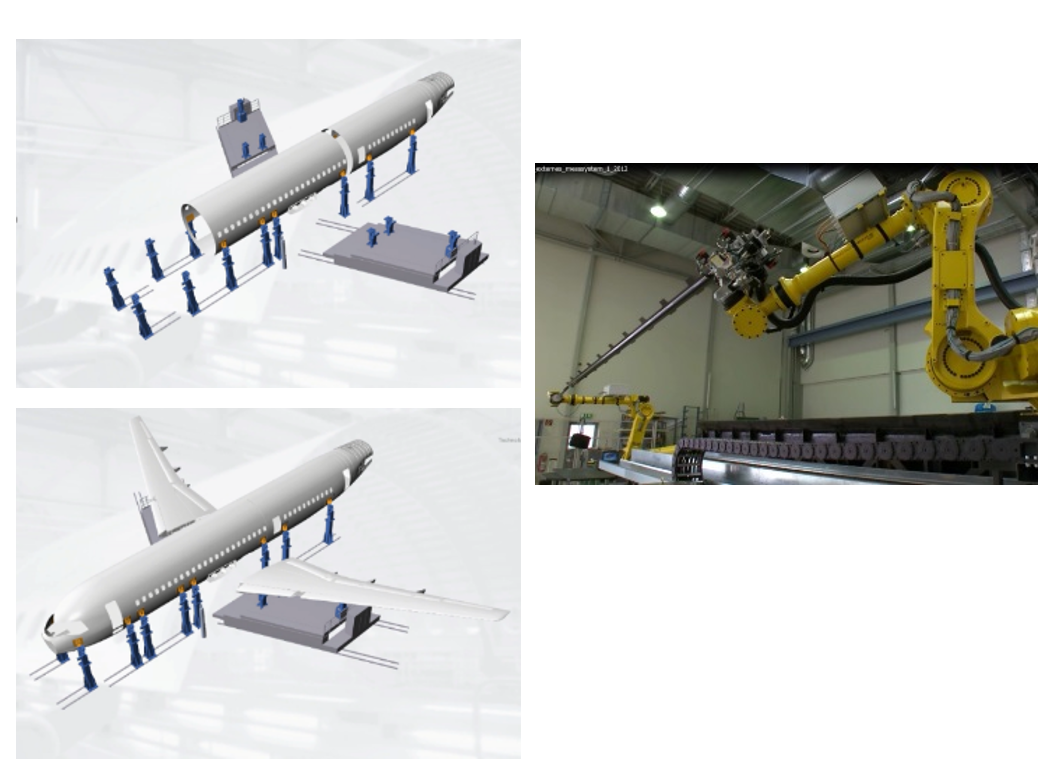

MAA(6DoF)

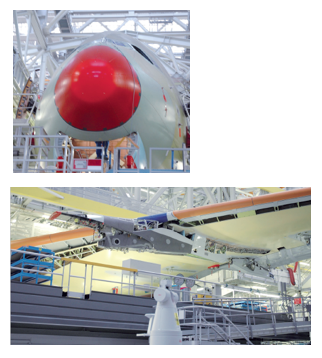

Automated assembly of aircraft with the reflector

(AirBus A380)

MAA(6DoF)

Automated assembly of aircraft with the reflector

(AirBus MILITARY)

MAA(7DoF)

Automated assembly of aircraft with T-Mac or

real-time feedback