The PRESTO system is a modular robotics and automation system that streamlines quality control in the

manufacturing process. By mounting a non-contact scanner on a robotic arm and tracking it with a laser

tracker, it fully automates the process from measurement to the output of result reports. While conventional

contact-based measuring instruments only acquire point and line data, the line-laser scanner quickly and

accurately captures the surface shape as 3D data without touching the object. By leveraging this 3D data,

the system solves various challenges in the manufacturing process and accelerates our customers’

manufacturing productivity.

Key features for Robotics and automation

Modularity and scalability

The PRESTO system is available in three packages—M, L, and XL—each employing a modular system that allows

for specifications to be modified by combining different units. For example, changes can be made, such as

whether the tracker is fixed or has a lifting mechanism, the position of the tracker rail (left or right),

and the inclusion of a turntable. This enables flexible adaptation to meet various customer needs. When

considering future cell expansion, the system can be upgraded by adding components, rather than requiring a

complete replacement.

Fast and high-quality scanning data capturing

The AS1 scanner can acquire up to 1.2 million data points per second at a line frequency of 300 Hz. The ultra-high-speed, high-density 3D data it captures is of exceptional quality, and the scanner is renowned for its outstanding accuracy in extracting features such as holes and edges—a hallmark of the line laser method.

In addition, typical automotive press and assembly parts can be measured within just a few minutes, while even a white body can be measured in as little as 30 to 60 minutes.

Spray-free measurement even on glossy surfaces

With our innovative SHINE – Systematic High-Intelligence Noise Elimination- technology, stable measurement of various surfaces is possible. From glossy black plastic automotive body parts to molded carbon fiber components, it provides clean, noise-free data completely without the need for spraying.

Target marker-less measurement for less worker load

In camera-based measurement systems, it is typically necessary to attach target markers to the object or set up a pre-prepared marker frame around it in order to combine multiple sets of measurement data and maintain accuracy. However, data is often missing from areas where markers are attached, and the process of attaching and removing markers is commonly cited as a bottleneck.

By using a laser tracker, it is possible to acquire scan data while maintaining a consistent global coordinate system, enabling completely marker-less measurement. This eliminates the need for time-consuming marker preparation—previously a bottleneck—and ensures there is no risk of missing data due to marker placement.

PRESTO System Product Lineup

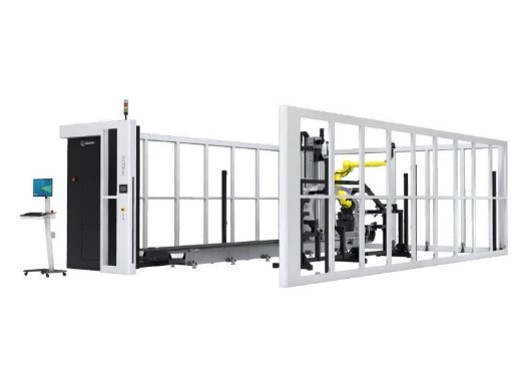

PRESTO M

This package utilizes a rotary table and is designed to operate with a single robot. It is an ideal solution for measuring small to medium-sized parts.

- Compatible with parts ranging from 1 to 3 meters in diameter

- 360° scanning

- Rotary table load capacity: up to 3 tons

PRESTO L

This package features a robot mounted on a travel rail and uses a tracker from one side. It is an ideal solution for measuring long parts.

- For parts up to 6 m

(length can be customized) - 180° scanning

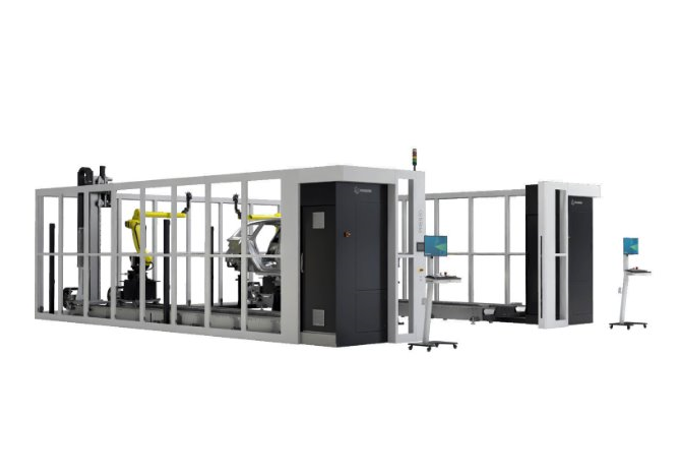

PRESTO XL

This double-arm package places robots and trackers on both sides, making it the ideal solution for automotive body measurement.

- For parts up to 6 m

(length can be customized) - 180° scanning

| PRESTO M | PRESTO L | PRESTO XL | |

|---|---|---|---|

| Equipment Size | 4,500 x 4,580 x 3,400 mm³ | 10,000 x 5,500 x 3,400 mm³ | 10,000 x 7,500 x 3,400 mm³ |

| Maximum Size |

Rotation table:φ3,000mm | Rotation Table:φ3,000mm Measurement area:6,000 x 2,500 x 2,000mm |

Measurement area:6,000 x 2,500 x 2,000mm |

| Weight Capacity | 3,500 kg | 4,800 kg | 8,800 kg |

For further details on specifications, please see the catalog.

Compatible Laser Tracker and Scanner

Inspection and Programming Software

Robot programming and inspection software

HRA (HxGN Robotic Automation)

Specification and inquiries

Please feel free to contact us for demo and questions regarding the system from the link below. Our industry leading consultants are happy to support you.