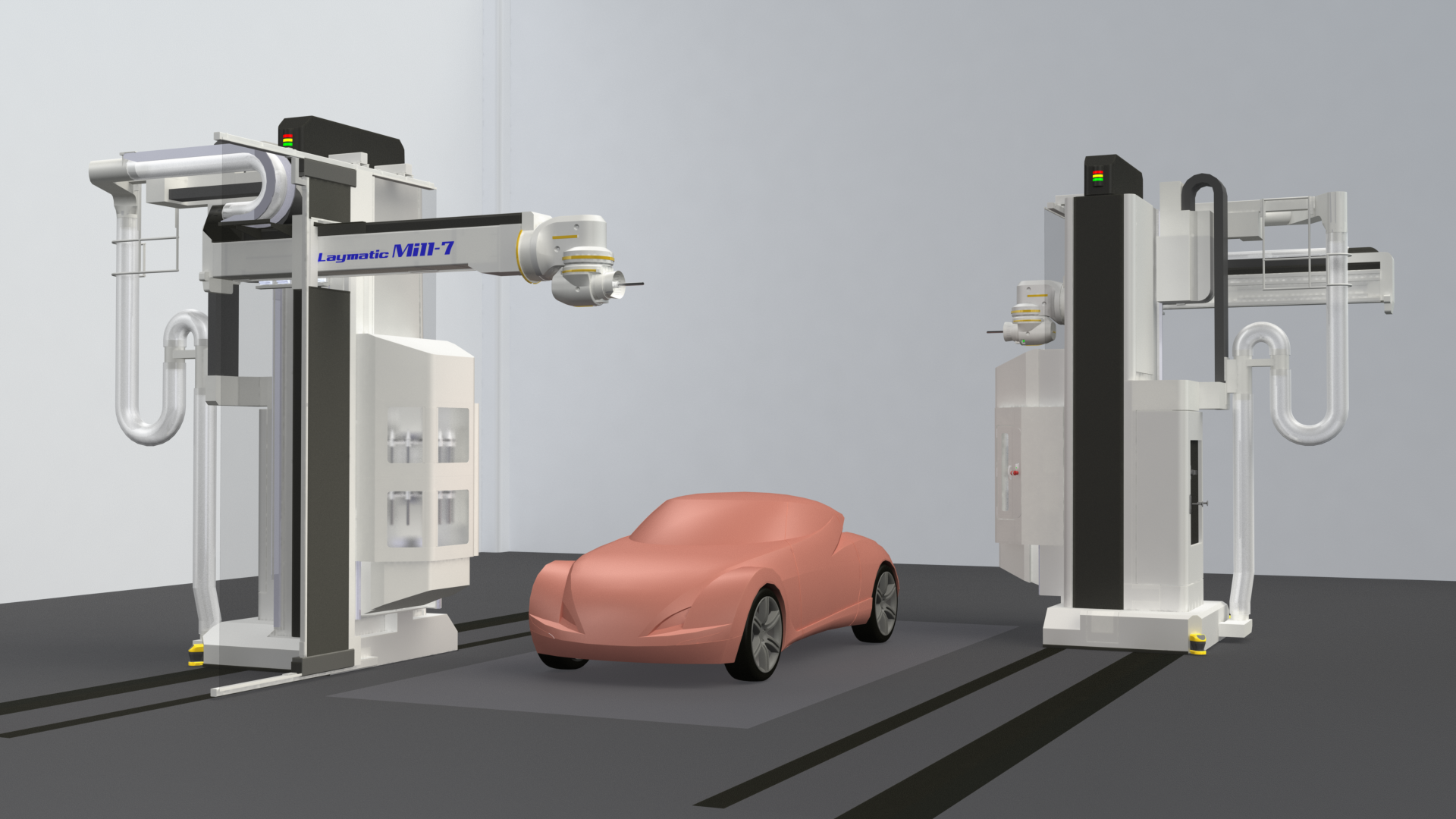

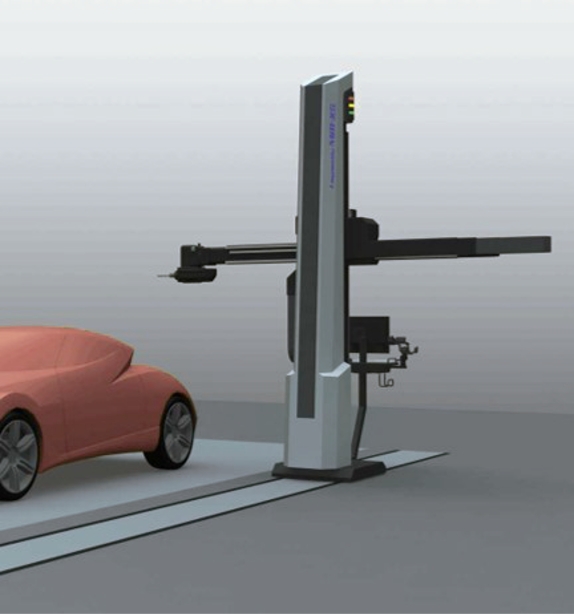

The Laymatic Mill-XS is our smart-priced model milling center designed as a compact entry-level machine.

It provides high cost-performance, making it ideal for users seeking excellent efficiency and flexibility.

Optimal Performance for Studio Installation

Cutting speed: 20 m/min

Spindle rotation speed: 18,000 min-1

With a compact footprint suitable even for studio environments, the machine provides sufficient specifications and performance for model creation.

Standard Equipment with Essential Functions

To deliver high cost-performance, the Laymatic Mill-XS is equipped with only the most essential functions, simplifying specifications while maintaining the performance required for model milling.

Speed, Rotation, and Milling Area

- Travel speed: 20 m/min

- Spindle rotation: 18,000 min-1

- Milling area: 1,500mm✖2,120mm✖30,000mm (min. stroke 160mm)

Accurate Physical Model Milling Using Digital Data

Based on digital data created by the customer, the Laymatic Mill-XS processes accurate physical models.

It supports precise milling for surface inspection, component fitting, or verification before mass production.

High Operability Through User-Friendly Controls

The system adopts an intuitive control interface that even first-time operators can use comfortably. With straightforward and easy-to-understand operation, milling can be performed efficiently. Operation training at the time of installation can be completed in as little as two days (excluding CAM functions). The system is also equipped with NC data editing capabilities.

Safe and Reliable Nighttime Unmanned Operation

Safety sensors on the machine help ensure stable nighttime unmanned operation.

By preventing unexpected events during milling, the system offers enhanced reliability and reduced labor requirements.

On-demand Video of Milling Machines

Laymatic Mill-X (JP)

Simultaneous 5-Axis Model Milling Center

Laymatic Mill-X (EN)

五轴联动模型加工器(CN)