The culmination of 40 years! Real-time analysis / arm-type articulated 3D measurement system

- Product Description

-

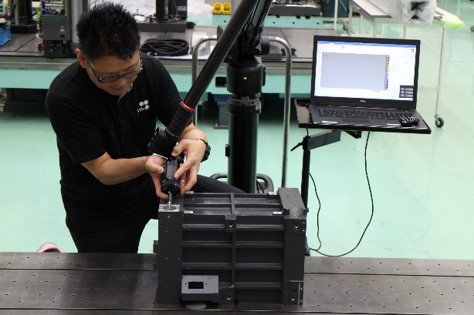

This is the industry’s only Made in Japan articulated 3D measurement system with the longest history and largest record of use in the Japanese market.

Using contact probe and non-contact laser, it is used in all quality control work, dimension inspection, assembly inspection, CAD comparison, deformation analysis, reverse engineering, etc.

Based on the concept of a system that anyone can easily measure anywhere, it is used mainly in the development and manufacturing sites of automobiles, such as automobile press and resin parts, jigs, and inspection tools.

It is also used in a wide range of industries such as heavy industry, construction machinery, government offices, and home appliances.

Product Features

Pride of ALL MADE IN JAPAN

The industry’s only fully domestic articulated 3D measurement system, developed at the request of Japanese automotive customers.

The arm is developed and designed by Kosaka Laboratory Ltd., which has a factory in Misato, Saitama Prefecture. TTS is in charge of developing and selling data processing and analysis software.

Vectoron developed based on the requirement of Japanese customers, promises design structure meeting the needs of the site, detailed support , maintenance response capabilities and long-term parts supply due to its domestic production. Also, unlike overseas products, there is no expensive hardware maintenance costs, and the running costs can be reduced.

TTS Customized Package

TTS strength lies in engineering and customizing packages tailored to the customer’s unique specifications. It is our uniqueness that we develop products by discussing with customers at actual site. Also TTS supports various types of customization, for example, a tower type Vectoron integrated with a surface plate that can measure the vertical/base direction at once, a special probe tailored to the application, dedicated measurement function for work leveling, a form function of automatic output and data aggregation trend management, etc

High-precision arm and in-house developed non-contact laser sensor

Vectoron is a portable measurement system that can be easily carried without the need for preparation before measurement, complicated setup and precision adjustment.

The arm type is a highly flexible measurement system that can easily measure products with complicated shapes and complicated structures.

Measurement methods that contribute to time savings and innovation in measurement work

- Contact probe measurement: Dimensions and geometric elements measurement

- Non-contact laser measurement: surface shape, deformation, distortion, etc.

Easy calibration

Stable measurement accuracy can be maintained because the accuracy check function is equipped as standard. It is possible for customers to adjust the accuracy themselves and grasp the operation status of each part of the main unit in real time, which speeds up maintenance and troubleshooting.

High-precision, lightweight arm designed based on ergonomics

Equipped with a new flexible brake that can fix the arm at any location, relieving workers from the fatigue of on-site work.

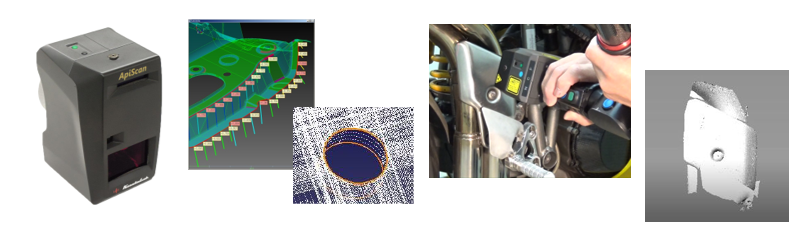

Non-Contact Laser Measurement

ApiScan Scanning System

For various purposes such as non-contact data, holes, fine shape, and luster materials

RaptorEye2 Scanning System

The world’s fastest sensor for instant analysis of the shape and larger sample size.

Control and Analysis Software

Either 3D-Magic REGALIS or Polyworks can be selected depending on the application.

Product Specifications

| Model | VMC7000M | VMC7000L | |

|---|---|---|---|

| Probe maximum move range | X-axis direction | 3500mm | 3900mm |

| Y-axis direction | 3500mm | 3900mm | |

| Z-axis direction | 3312mm | 3712mm | |

| Accuracy (based on our standards) |

Fixed point reproducibility | 2σ:0.03mm | 2σ:0.05mm |

| Contact-type measurement accuracy | 2σ:0.04mm | 2σ:0.063mm | |

| Non-contact measurement accuracy | ±0.06mm | ±0.08mm | |

| Measuring arm | Total length | 1750mm | 1950mm |

| Freedom | 7 joints | 7 joints | |

| Mass | Approx. 12kg (includes non-contact controller) | Approx. 13kg (includes non-contact controller) | |

| Power supply | AC100~240V, 50/60Hz, 115VA(does not include PC) | ||

| Device weight | VTL03 specifications | Approx. 21kg | Approx. 22kg |

| VTL41 specifications | Approx. 108kg | Approx. 109kg | |

| VTL60 specifications | Approx. 77kg | Approx. 78kg | |

| Sensor spec | Model | PU-OL100-SP | |

| Size | 76(W)×106(D)×124.6(H)mm | ||

| Weight | Approx. 640g | ||

| Beam diameter | φ0.183 mm or less | ||

| Measurement Z width | 60mm | ||

| Stand off | 145~205mm | ||

| X Pitch | 0.016~0.063 | ||

| Visual field length (width) | 21.56~213.54mm | ||

| points per line | 201 to 513 points per line | ||

| Measurement lines | 30 to 60 lines per second | ||

Related Solution

-

<3D-magic REGALIS>Software that anybody can use.

-

Automation of measurement work, data processing, and report creation by Vectoron

Application

- Press

・Automobile press

・Precision press

・Covers - Die

- Casting

・Molds

・Cores

・Products - Die casting

・Products

・Die maintenance - Vehicles

- Large welded structures

・Automotive body

・Construction and agricultural machinery

・Heavy industrial components - Resin molded products

・Bumpers

・Covers

・Interiors, etc. - Jig and inspection tools

- Metal processing products

- Clay models

- Fiber and fabric materials

- Measurement of forged and fabricated materials

・Carbon fibers

・Foaming agents

・Large casting - Pipes

- In-process measurement

- In-line trend inspection