The Vectron is a multi-joint articulated arm coordinate measuring machine featuring seven joints for exceptional flexibility and high degrees of freedom in measurement. With over 40 years of development—primarily for the Japanese automotive industry—it is widely used across a range of manufacturing sectors, including heavy industry, construction machinery, government agencies, and steel production.

Capable of measuring complex shapes and intricate structures with ease, the Vectron allows for fast and simple operation without the need for extensive setup, complicated fixtures, or precision adjustments. Its lightweight, portable design enables convenient on-site measurements.

The VMC8000 Series enhances the core performance of previous models, offering smoother, more agile movement. It supports both contact and non-contact measurements across a variety of workpieces and geometries.

Notice of End of Maintenance Support for Vectron [Updated: 2025.05.08]

We regret to inform you that maintenance support for the product has ended, as outlined in the link below.

We kindly ask for your understanding and continued support.

What is an Articulated Arm CMM?

An articulated arm coordinate measuring machine (CMM) is a 3D measurement device that uses a multi-joint arm to achieve highly flexible and precise measurement.

Its design allows for easy access to confined spaces and complex-shaped workpieces, making it widely used in manufacturing and quality control environments where high-accuracy data acquisition is essential.

Key Features of the VECTORON 8000 Series Articulated Arm CMM

High-Precision Articulated Arm

The arm is ergonomically designed with optimized proportions, a magnetic lock system, and lightweight materials to minimize operator fatigue and stress during use.

Its six-joint articulated structure enables smooth and accurate measurement of complex geometries, intricate contours, and objects with varying height levels.

In addition, it provides high-precision measurement of geometric features such as holes.

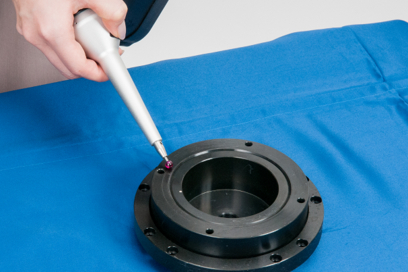

A Wide Variety of Contact Probes

The probe at the tip can be easily replaced to suit different applications.

This allows for accurate measurement of hard-to-reach areas, such as deep recesses or the bottom of cylindrical holes.

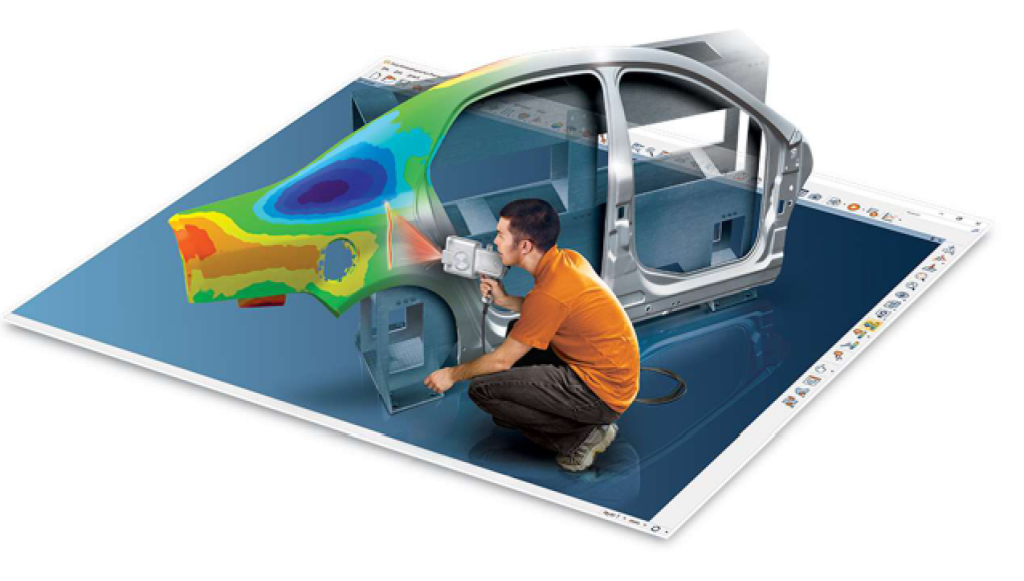

High-Precision Non-Contact Scanner

You can select the most suitable non-contact sensor based on your specific measurement workpieces and applications.

Flying Dot Type Scanner ApiScan

Enables high-precision measurement of glossy surfaces, such as piano-black finishes, as well as holes, edges, and fine features — all without the need for spray.

Laser Triangulation Scanner RaptorEye2

Capable of high-speed scanning at 400 Hz with 660,000 points per second, enabling rapid surface data acquisition and significantly reducing measurement time.

Versatile 3D Scanning and Measurement Support

The maximum measurement range in a single operation is approximately 2,500 mm. However, with features such as coordinate stitching and integration with laser trackers (Smart Alignment), it is possible to measure large objects beyond the arm’s standard reach.

Here, we introduce the unique capabilities exclusive to VECTORON.

With the push of a button, the arm can be locked at any desired position, eliminating the hassle of returning the arm to the home position during measurement.

With battery power and Wi-Fi connectivity, measurements can be performed in environments where power sources are difficult to access or where cables would obstruct operations, such as on machining equipment.

When there are significant changes in the measurement environment or if accuracy becomes unstable, customers can perform a simple calibration procedure themselves to maintain and manage measurement accuracy.

Our engineers provide annual calibration services and quickly handle any unexpected failures or malfunctions at our domestic factory.

Additionally, we have established a dedicated support center to ensure our customers can use the products comfortably.

The support center is available on weekdays from 9:00 AM to 5:00 PM, offering assistance for both hardware and software through a single point of contact via email or phone.

We are also committed to helping customers solve any issues or challenges they may face during measurement.

Developed in response to requests from domestic automotive manufacturers, this is the industry’s only domestically produced articulated arm coordinate measuring machine.

The hardware is developed by Kosaka Laboratory, while the software is developed in-house by our company.

Software for Precise Control and Analysis in 3D Measurement

Customers can choose either 3D-MagicREGALIS or Polyworks according to their specific application needs.

Related Information Supporting 3D Scan Quality

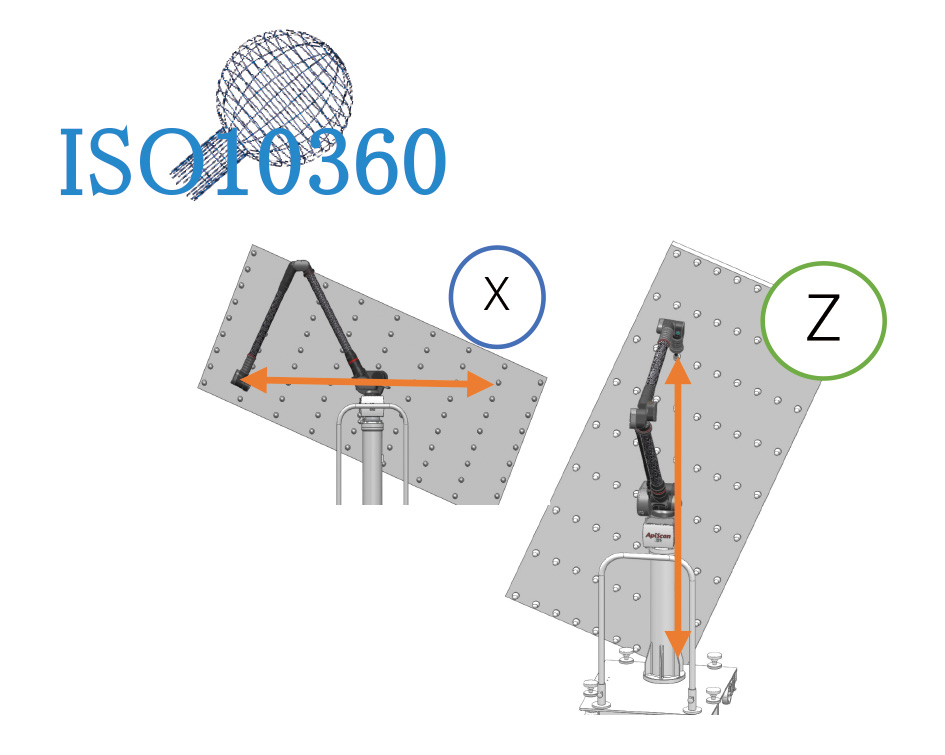

ISO 10360-Compliant for CMM Accuracy Assurance

Established an accuracy assurance system using in-house developed gauges.

Robust Arm and Sleek Design with Innovative Structural Engineering

By reviewing and redesigning each joint structure, measurement accuracy has been improved, and the system maintains stable precision even under changing site conditions, outperforming previous models.

Use Cases of Articulated Arm Coordinate Measuring Machines

Pressing

・Automotive Press

・Precision Press

・Covers

・Molds (General)

Casting

・Casting Molds

・Cores

・Products

Die Casting

・Products

・Mold Maintenance

Vehicles

Large Welded Structures

・Automotive Bodies

・Construction and Agricultural Machinery

・Heavy Industry Components

Resin Molded Parts

・Bumpers

・Covers

・Interior Parts, etc.

Jigs and Inspection Fixtures

Metal Processed Components

Clay Models

Textiles and Fabric Materials

Measurement of Near-Net-Shape Materials

・Carbon Components

・Foamed Materials

・Large Castings

Various Types of Pipes

On-Machine Measurement

Inline Trend Monitoring

Users of the VECTORON Articulated Arm CMM

High-Accuracy Non-Contact 3D Scanner

Ask About Our Articulated Arm CMM

Please feel free to contact us for the VECTORON 8000 Series catalog or any inquiries.