The Leica Absolute Tracker ATS800 delivers high-precision, high-speed scanning and seamless workflow integration—enabling efficient large-scale inspection and 3D scanning. It captures complex geometries quickly and accurately from distances of up to 40 meters. Ideal for aerospace, automotive, and energy sectors, the ATS800 excels in demanding large-scale manufacturing environments.

ISO 10360-10: Compliance for Laser Tracker Measurement

The Leica Absolute Tracker is fully compliant with ISO 10360-10, the international standard that defines performance evaluation methods for laser tracker measurement. This standard guarantees measurement accuracy and reliability against globally recognized benchmarks, ensuring confidence across a wide range of applications from manufacturing to quality inspection. With performance certified to international standards, the Leica Absolute Tracker is ready to meet even the most demanding global quality requirements.

Key Features of the Leica Absolute Tracker ATS800

Direct scanning enables high-accuracy 3D measurement of large structures, even in harsh outdoor environments. By combining rapid, precise scanning with advanced surface recognition tools, the system makes it easy and safe to capture fine edges, features, and surfaces remotely.

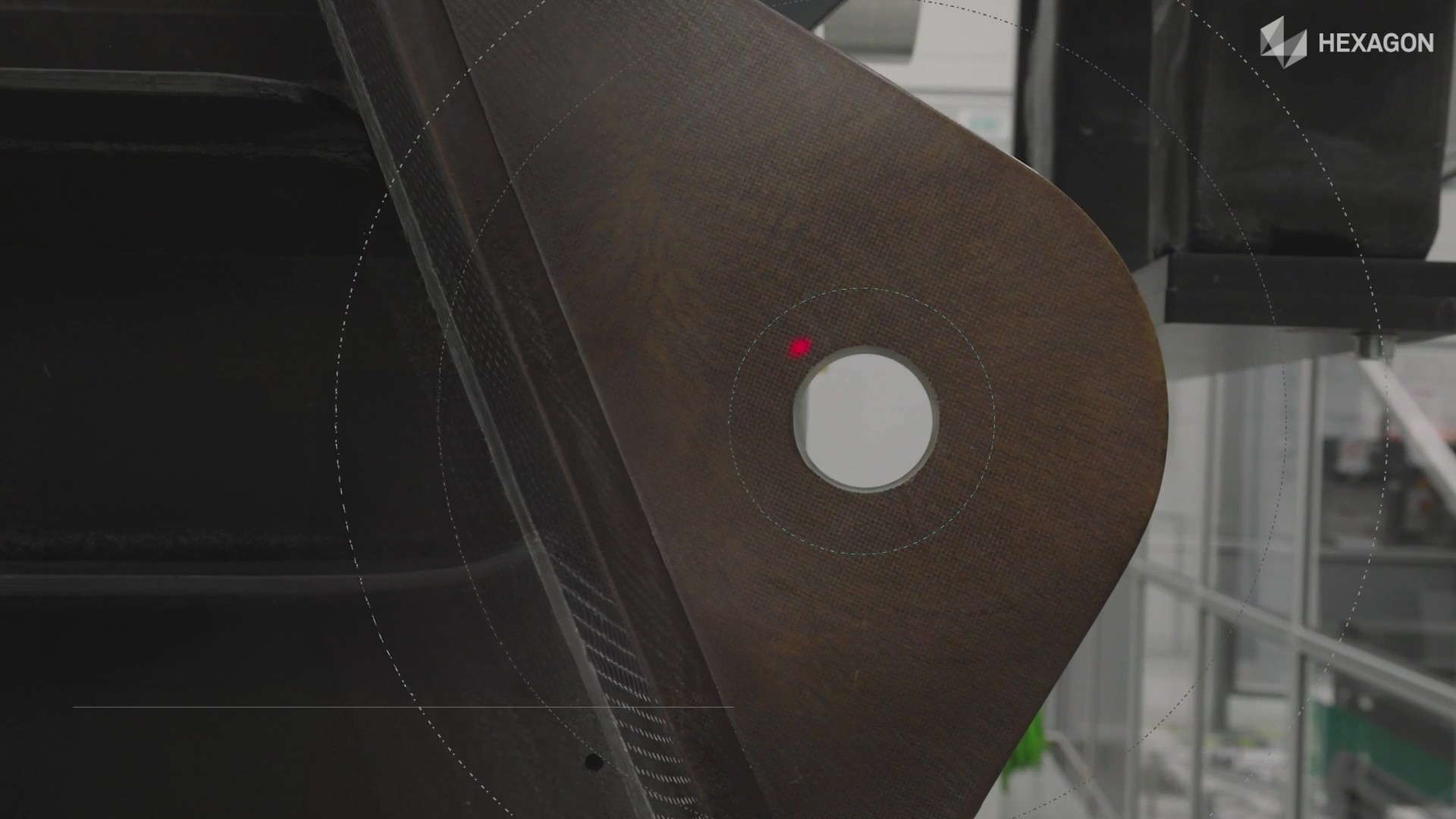

Precision scanning enables detailed recognition of fine features, allowing complex shapes to be scanned quickly and accurately on the production line. Users can define specific scan areas, ensuring uniform point distribution within the selected region for consistent and reliable results. The system also incorporates TruePoint Technology, which pinpoints the center of the measurement area to maintain optimal accuracy. By enhancing yield and reducing rework, TruePoint contributes directly to time and cost savings in manufacturing processes.

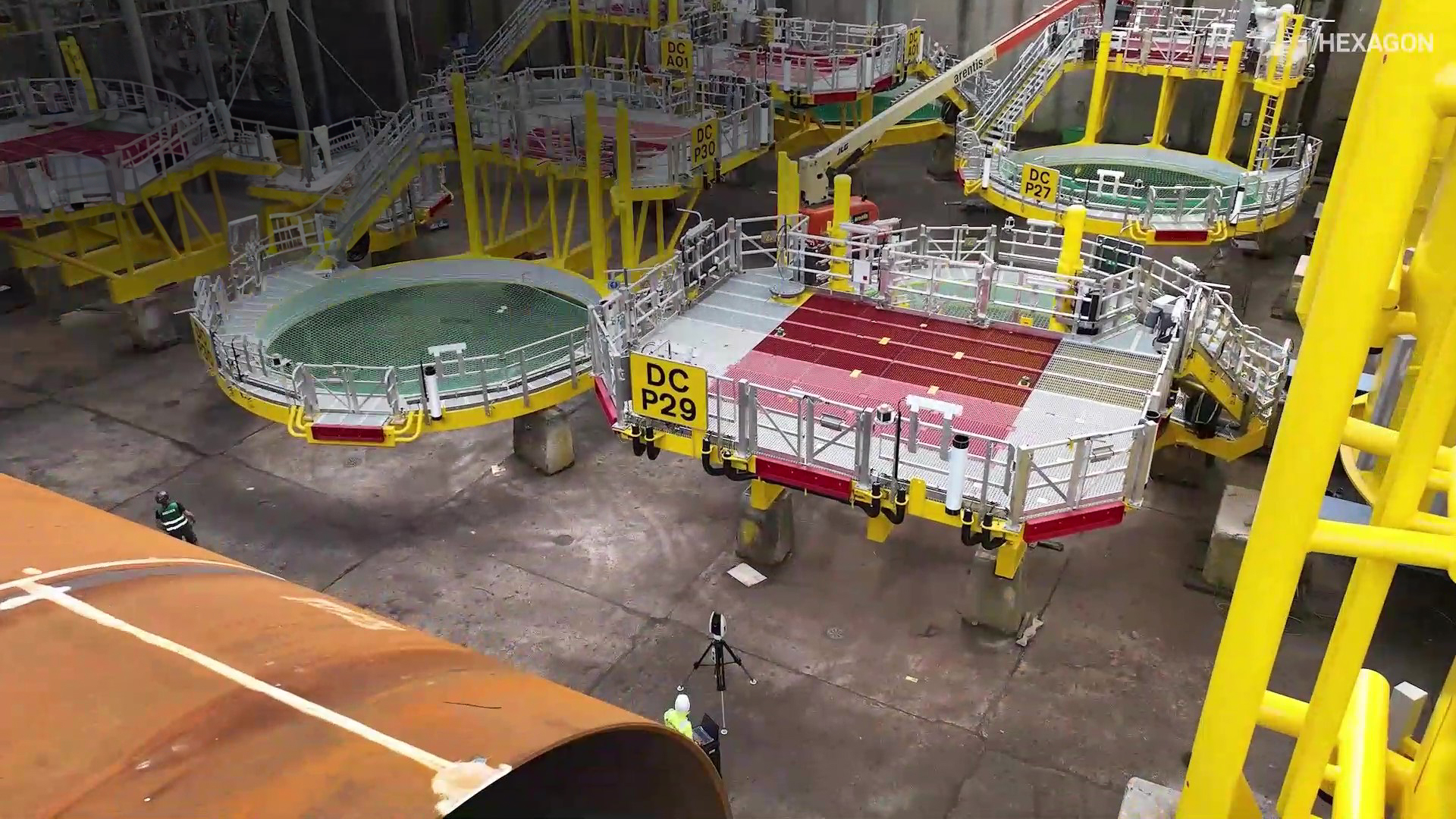

Safe Long-Range 3D Scanning

The system enables scanning of large objects from a distance, making it perfectly suited for inspection tasks in industries such as aerospace and energy where large assemblies are common. Remote operation and scanning capabilities ensure operator safety, even in cluttered or hazardous environments.

3D Measurement in Harsh Environments | IP54 Rated

With an IP54 protection rating, the Leica Absolute Tracker ATS800 is resistant to dust and water, ensuring dependable operation in challenging environments. Its compact, portable design—with integrated Wi-Fi and battery power—makes it easy to transport and deploy anywhere. The ATS800 delivers both reliability and versatility in every application.

Automatic Hole and Edge Detection with AI | FeatureDetect

By utilizing the FeatureDetect function, AI is leveraged to automatically identify features such as holes and edges. This enables efficient measurement while maintaining consistency. Early detection of defects helps improve yield and contributes to overall quality enhancement.

Fast and High-Precision Measurement of Automotive White Bodies

Automation of inspection processes in the automotive industry goes beyond simply reducing measurement effort—it standardizes quality inspection variability and digitizes inspection results. The Leica Absolute Tracker ATS800’s direct scanning enables high-precision, speedy measurements that accelerate various manufacturing processes.

In-Line Measurement with Laser Tracker

Integrating the Leica Absolute Tracker ATS800 into your production line enables in-line measurement, accelerating manufacturing processes. By directly embedding quality inspection within the production flow, it helps reduce labor and improve efficiency.

Case Studies: Large-Scale Structure Measurement with Laser Trackers

Customer Success Stories Using 3D Measurement Systems

Complementary Tools for Enhancing 3D Measurement Efficiency

Laser Tracker Products Enabling Fast and Accurate 3D Scanning

Learn More: Specs, Webinars & Expert Support

We are here to support you in solving challenges related to large-scale structure measurement. Please feel free to contact us for demos, benchmarks, and any other inquiries.